How to Adjust Mechanical Disc Brakes marks the start of a practical journey into enhancing your cycling experience. This guide delves deeply into the essential components and significance of proper brake adjustment, which greatly influences both performance and safety. Understanding how to tackle common issues stemming from misalignment ensures a smoother, more enjoyable ride.

In this comprehensive overview, you will find detailed instructions on the necessary tools, a step-by-step procedure for making adjustments, and practical maintenance tips to prolong the life of your brakes. Furthermore, we will explore common problems encountered during adjustments and their respective solutions, ensuring you are well-equipped to handle any challenges that may arise.

Introduction to Mechanical Disc Brakes

Mechanical disc brakes are a crucial component in modern cycling and automotive systems, providing reliable stopping power and safety. Their design consists of several essential parts, including the brake rotor, caliper, and brake pads. The rotor, typically mounted to the wheel, rotates with it, while the caliper houses the brake pads and is responsible for applying pressure to the pads against the rotor to create friction.

Understanding these components and their function is vital for effective brake maintenance and performance enhancement.Proper adjustment of mechanical disc brakes directly impacts both performance and safety. A well-adjusted brake system ensures consistent and responsive braking, which is essential for preventing accidents and ensuring rider confidence. Misalignment or incorrect adjustment can lead to various issues, such as brake drag, inconsistent braking power, or even complete brake failure.

Therefore, maintaining optimal alignment and settings is not just a matter of convenience; it is a critical safety measure for both cyclists and vehicle operators.

Components of Mechanical Disc Brakes

The main components of mechanical disc brakes include the following:

- Brake Rotor: A circular disc that rotates with the wheel, providing a surface for the brake pads to clamp against.

- Caliper: The device containing the brake pads, which are pushed against the rotor to create the necessary friction for braking.

- Brake Pads: Friction material that presses against the rotor to slow down or stop the wheel’s rotation.

- Cable System: Transfers the rider’s input from the brake lever to the caliper, enabling brake engagement.

- Mounting Hardware: Connects the caliper to the bike frame or fork, ensuring stability during braking.

Importance of Proper Adjustment

Ensuring proper adjustment of mechanical disc brakes is vital for several reasons:

- Performance: Accurate alignment and adjustment facilitate optimal contact between the brake pads and the rotor, enhancing stopping efficiency.

- Safety: Well-adjusted brakes minimize the risk of brake failure, providing reliable performance during critical moments.

- Longevity: Proper adjustments prevent uneven wear on brake components, extending their lifespan and reducing maintenance costs.

Common Issues Caused by Misalignment

Misalignment and incorrect adjustment can lead to various common issues in mechanical disc brakes, negatively impacting performance.

- Brake Drag: Occurs when the brake pads are constantly in contact with the rotor, leading to premature wear and overheating.

- Inconsistent Braking: Misalignment can cause uneven pressure on the rotor, resulting in unpredictable stopping power, which can be dangerous.

- Noise: A misaligned brake system may produce squeaking or grinding sounds, indicating that the brake pads are not making proper contact.

- Reduced Lifespan: Improperly adjusted brakes tend to wear out faster, necessitating more frequent replacements and repairs.

Tools and Materials Needed for Adjustment

When adjusting mechanical disc brakes, having the right tools and materials is essential for ensuring a successful and efficient process. Proper equipment not only makes the adjustment easier but also enhances the accuracy of the alignment and tension settings. Below is a list of the essential tools and materials needed for a smooth adjustment process.

Essential Tools for Brake Adjustment

The following tools are vital for making precise adjustments to mechanical disc brakes. Utilizing proper tools helps maintain optimal braking performance and prolongs the life of the braking system.

| Tool | Purpose |

|---|---|

| Hex Wrench Set | Used to adjust the brake caliper and rotor alignment. |

| Screwdriver Set | Helps in tightening or loosening screws on the brake assembly. |

| Torque Wrench | Ensures that bolts are tightened to the manufacturer’s specified torque. |

| Pliers | Useful for pulling cables and making minor adjustments. |

| Brake Pad Spreader | Facilitates the repositioning of brake pads for alignment. |

Additional Materials for the Adjustment Process

In addition to tools, certain materials may be required during the adjustment of mechanical disc brakes. These materials help ensure that the brakes function optimally and safely.Before beginning the adjustment, it is advisable to gather the following materials:

- Brake Cleaner: Ensures that brake components are free from dirt and grease.

- Lubricant: Helps in reducing friction on moving parts, facilitating smoother operation.

- Replacement Brake Pads: Useful in case the existing pads are worn out or damaged.

- Brake Cable: A replacement may be necessary if the current cable shows signs of wear or damage.

- Rags or Towels: Essential for wiping down components and maintaining cleanliness during the process.

Using the right tools and materials is crucial for achieving effective mechanical disc brake adjustments, ensuring both safety and performance.

Step-by-Step Procedure for Adjusting Mechanical Disc Brakes

Before proceeding with the adjustment of mechanical disc brakes, it is essential to perform initial checks to ensure that the brakes are functioning correctly and that all components are in satisfactory condition. These checks help to identify any underlying issues that may affect the adjustment process.Initial checks to consider include:

- Inspecting the brake pads for wear. Ensure that they are not excessively worn down and still possess adequate material for effective braking.

- Checking the rotor for damage or warping. A warped rotor can lead to uneven brake pressure and reduced performance.

- Ensuring that the cables and housing are not frayed or damaged, as this can impact the brake’s responsiveness.

Once the initial checks are completed, follow the detailed step-by-step guide for adjusting the mechanical disc brakes. This process will help ensure optimal brake performance and safety.

Adjustment Process

The adjustment process for mechanical disc brakes involves several key steps that require precision and attention to detail. Below is a structured approach to effectively adjust your brakes.

Loosen the Brake Cable

Locate the cable anchor bolt and use the appropriate tool to loosen it.

- Ensure you have enough slack in the cable to adjust the brake pads without resistance.

- Center the Brake Caliper

Squeeze the brake lever to bring the brake pads into contact with the rotor.

- While holding the lever, tighten the cable anchor bolt to secure the caliper in the centered position.

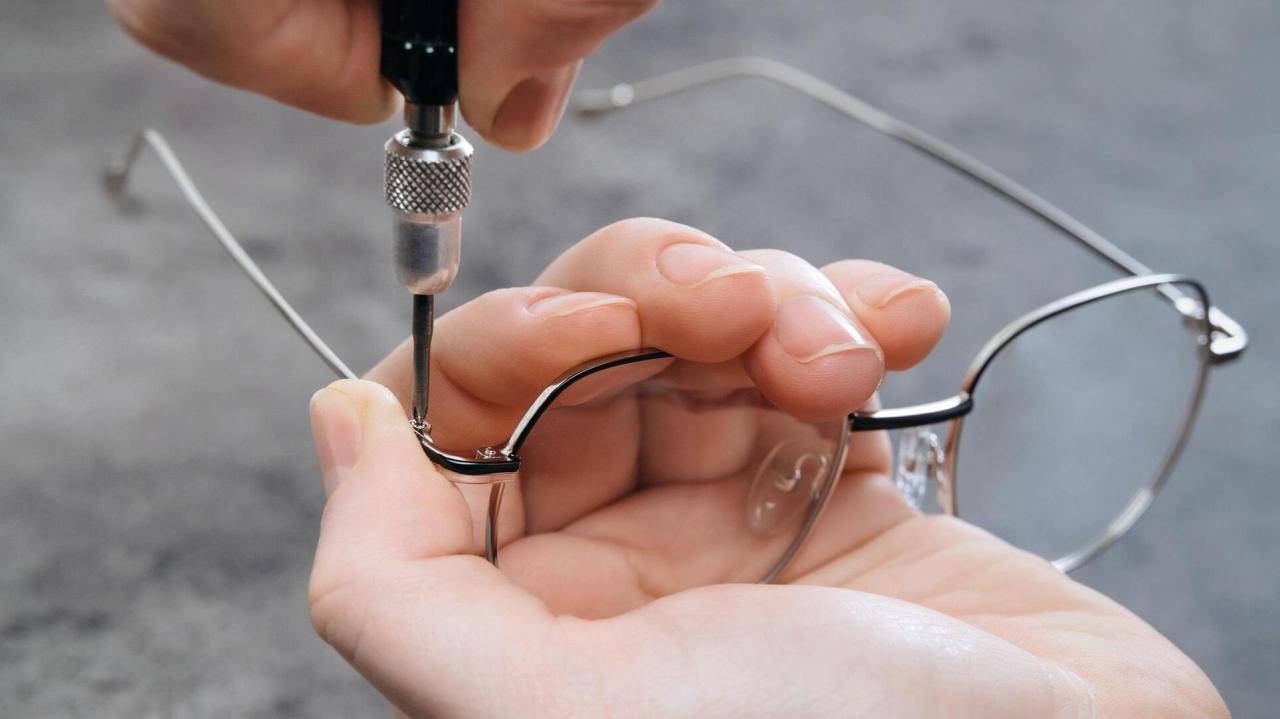

- Adjust the Brake Pads

Identify the adjustment screws on the caliper. These screws allow fine-tuning of the pad’s position relative to the rotor.

Utilize a suitable screwdriver to turn the adjustment screws.

- Rotate the screws incrementally, checking the distance between the rotor and the pads. Aim for a gap of approximately 1-2 mm.

- Test the Brake Function

Release the brake lever and spin the wheel to check for any rubbing of the pads against the rotor.

- If the pads rub against the rotor, repeat the adjustment of the caliper until the wheel rotates freely without obstruction.

- Final Cable Tension Adjustment

Once the pads are correctly positioned, recheck the cable tension.

- Pull the brake lever to ensure it feels firm and responsive; adjust the cable tension as necessary at the anchor bolt.

- Final Checks

Ensure all bolts and adjustments are secure.

Conduct a final test by squeezing the brake lever multiple times to confirm that the brake pads engage properly and that there is no noise or dragging.

The above steps, when followed carefully, will aid in achieving optimal performance from the mechanical disc brakes, enhancing safety and reliability while riding.

Common Problems and Solutions

Adjusting mechanical disc brakes can occasionally lead to various issues that may impede their functionality. Understanding these common problems not only aids in effective troubleshooting but also helps in maintaining optimal braking performance. Below, we delve into some frequent complications encountered during brake adjustments and their corresponding solutions.Recognizing the symptoms of brake adjustment issues is crucial for addressing them promptly.

The following table summarizes common problems, their symptoms, and the corrective actions to take, providing clarity and guidance for effective troubleshooting.

| Common Problem | Symptoms | Corrective Actions |

|---|---|---|

| Brake Pads Not Engaging Fully | Weak braking response, excessive lever travel | Check the cable tension and adjust as necessary; ensure pads are aligned properly against the rotor. |

| Brake Pad Wear Unevenly | Noise during braking, reduced braking efficiency | Inspect the caliper alignment; adjust to ensure even contact with the rotor; consider replacing worn pads. |

| Brake Lever Feels Spongy | Inconsistent braking power, lever feels soft | Check for air in the brake line; bleed the brakes if necessary to remove any trapped air. |

| Brake Rotor Warping | Vibrations during braking, uneven pad wear | Examine the rotor for any signs of warping; either true the rotor or replace it if necessary. |

| Brake Cable Fraying | Difficulty in pulling lever, inconsistent brake response | Inspect the brake cable for damage; replace the cable if fraying is evident. |

“Regular maintenance and timely adjustments can prevent most common brake issues.”

Maintenance Tips for Mechanical Disc Brakes

Regular maintenance of mechanical disc brakes is essential to ensure optimal performance and longevity. By following best practices for maintenance, you can minimize the need for frequent adjustments and enhance the overall safety and reliability of your braking system. Proper maintenance not only extends the life of your brake components but also contributes to a smoother and more responsive riding experience.To avoid common issues that necessitate adjustments, it is vital to establish a routine maintenance schedule.

This proactive approach can help identify wear or damage before they escalate into larger problems. Below are key maintenance tasks to perform regularly to keep your mechanical disc brakes in excellent condition:

Routine Maintenance Tasks for Mechanical Disc Brakes

Establishing a routine for maintaining your mechanical disc brakes can greatly reduce the risk of performance issues. The following tasks are crucial for ensuring reliable braking performance:

- Inspect Brake Pads: Regularly check the condition of the brake pads for wear. Replace them if they are worn down to the minimum thickness.

- Check Brake Cables: Inspect the cables for any signs of fraying, rust, or damage. Replace as necessary to maintain optimal tension and function.

- Clean Brake Components: Keep the rotors and calipers clean from dirt and debris. Use isopropyl alcohol and a clean rag to wipe down the surfaces.

- Ensure Proper Alignment: Verify that the brake calipers are aligned correctly with the rotors. Misalignment can lead to uneven wear and reduced braking efficiency.

- Adjust Cable Tension: Periodically check and adjust the cable tension to ensure that the brakes engage smoothly and effectively.

- Examine Rotor Condition: Inspect the rotors for warping, scoring, or excessive wear. Replace them if necessary to maintain effective braking performance.

- Lubricate Pivot Points: Apply a suitable lubricant to the pivot points of the brake calipers to ensure smooth operation and prevent rust.

- Test Brake Performance: Regularly test the brakes while riding to ensure they are functioning properly. Pay attention to any unusual sounds or changes in braking feel.

By adhering to these maintenance tips, you can ensure that your mechanical disc brakes operate efficiently, enhancing both safety and performance. Regular care will not only extend the lifespan of your brake components but also provide a more enjoyable riding experience without the disruption of unexpected adjustments.

Comparison with Other Brake Types

Mechanical disc brakes are one of the various braking systems utilized in bicycles and other vehicles. Their design and functionality differ significantly from hydraulic disc brakes, which are another popular braking option. Understanding these differences can aid in selecting the most suitable brake system for specific riding styles and conditions.Mechanical disc brakes operate via a cable system which pulls the brake pads against the rotor when the brake lever is engaged.

In contrast, hydraulic disc brakes utilize fluid pressure to achieve the same effect. This fundamental difference results in various advantages and disadvantages for each type of braking system.

Comparison of Mechanical Disc Brakes and Hydraulic Disc Brakes

Mechanical disc brakes and hydraulic disc brakes each offer unique benefits and drawbacks that can influence a rider’s choice.

Advantages of Mechanical Disc Brakes

Easier and more cost-effective to maintain and repair due to their simpler design and the use of cables.

Easily adjustable and can be serviced without specialized tools or fluid, making them user-friendly.

Generally lighter than their hydraulic counterparts, providing a slight weight advantage for performance-oriented riders.

Disadvantages of Mechanical Disc Brakes

Less modulation and stopping power compared to hydraulic systems, which can be a limitation in high-performance or downhill situations.

Prone to cable stretching, requiring frequent adjustments to maintain optimal performance.

More susceptible to environmental factors such as dirt and moisture, which can impact brake performance.

Advantages of Hydraulic Disc Brakes

Superior stopping power and modulation due to the nature of fluid dynamics, allowing for smoother and more controlled braking.

Reduced maintenance frequency as the system is sealed, minimizing exposure to dirt and debris.

Ideal for aggressive riding styles and conditions where consistent performance is crucial.

Disadvantages of Hydraulic Disc Brakes

Generally more expensive, both in initial cost and potential repair expenses.

More complex to adjust and service, often requiring specific tools and expertise.

Heavier than mechanical systems, which may be a consideration for racing or weight-sensitive applications.

Adjustments between mechanical and hydraulic systems also differ substantially. Mechanical disc brakes allow for straightforward adjustments by simply tightening or loosening the cable tension. In contrast, hydraulic disc brakes require bleeding the system to remove air bubbles and ensure optimal fluid pressure, a more complex process that can be daunting for inexperienced users.In summary, while mechanical disc brakes are often favored for their ease of maintenance and cost-effectiveness, hydraulic disc brakes provide enhanced performance, particularly in demanding riding conditions.

Riders should consider their specific needs and preferences when choosing between the two systems.

Safety Considerations

When adjusting mechanical disc brakes, it is essential to prioritize safety to prevent accidents and injuries. The process involves working with components that are critical for the effective functioning of your bicycle, and any oversight can lead to severe consequences while riding. Adhering to safety considerations not only protects the individual performing the adjustment but also ensures the safety of others on the road.Proper safety gear and precautions are vital during the brake adjustment process.

Always wear appropriate protective equipment, as this minimizes the risk of injury from sharp tools and mechanical parts. Understanding the necessary precautions can help create a safe environment for performing adjustments.

Essential Safety Gear

In order to maintain personal safety while adjusting mechanical disc brakes, the following protective gear is highly recommended:

- Safety Glasses: Protects your eyes from potential debris and fluid splashes during the adjustment process.

- Gloves: Prevents hand injuries and maintains cleanliness when handling brake components and lubricants.

- Closed-Toe Shoes: Reduces the risk of foot injuries from falling tools or equipment.

- Long Sleeves: Provides an added layer of protection against sharp edges and hot components.

The importance of having the right environment cannot be overstated. A well-organized workspace can significantly reduce the risk of accidents.

Checklist for a Safe Adjustment Environment

Creating a safe adjustment environment involves several key steps. Follow this checklist to ensure that all safety considerations are met:

- Clear the workspace of any clutter that may obstruct movement or pose tripping hazards.

- Ensure that the bike is securely positioned, using a bike stand if necessary, to prevent it from falling during adjustments.

- Have all necessary tools within reach to minimize unnecessary movement and distractions.

- Inspect all tools for any damage or wear before use to prevent failures during the adjustment.

- Work in a well-lit area to enhance visibility of the components being adjusted.

By adhering to these safety considerations and utilizing protective gear, you will create a safer environment for adjusting mechanical disc brakes. Ensuring that safety is a priority not only protects you but also enhances the overall performance and reliability of your braking system.

Resources for Further Learning

Expanding your knowledge about mechanical disc brakes and brake systems in general can greatly enhance your understanding and skill set. There are numerous resources available, ranging from books and websites to forums and communities dedicated to automotive and bicycle maintenance. Engaging with these materials will help you gain deeper insights and practical knowledge.Various resources are available to learners who wish to explore the intricacies of brake systems.

Below are some recommended materials and communities where you can seek guidance and share experiences:

Recommended Books and Websites

To deepen your understanding of mechanical disc brakes and related systems, consider the following books and websites. These resources provide comprehensive information and step-by-step guidance on brake maintenance and repair.

- The Bicycle Repair Manual by Chris Sidwells – A thorough guide covering various aspects of bicycle maintenance, including brake systems.

- Bicycle Maintenance for Dummies by Alan Johnson – Offers practical advice for bike maintenance, with a section dedicated to brakes.

- Park Tool’s Website

-An excellent resource for bike repair tutorials, tools, and maintenance tips. - Sheldon Brown’s Website

-A comprehensive source of information on bicycle mechanics, including braking systems. - How to Adjust Your Mechanical Disc Brakes

-A detailed online guide that specifically addresses brake adjustments and maintenance.

Forums and Communities

Engaging with fellow enthusiasts can provide invaluable insights and solutions to common problems. The following forums and communities are recommended for sharing knowledge and seeking advice:

- Bike Forums

-An extensive platform where users can discuss various bike-related topics, including brake systems. - Reddit – r/bicycling

-A community of bicycle lovers sharing tips, experiences, and advice about maintenance and upgrades. - MTBR Forum

-Focused on mountain biking, this forum has sections dedicated to bike maintenance and repairs. - Facebook Groups

-Various groups exist for bicycle repair enthusiasts where members can ask questions and share knowledge.

These resources offer a wealth of information for anyone interested in further exploring mechanical disc brakes and their maintenance. Engaging with books, websites, and community forums will equip you with the knowledge necessary to effectively adjust and maintain your brake systems while connecting with fellow enthusiasts who share your passion.

Conclusion

In conclusion, mastering the art of adjusting mechanical disc brakes not only enhances your cycling performance but also ensures your safety on the road. With the right tools and a clear understanding of the adjustment process, you can confidently address any issues and maintain your brake system effectively. Remember, regular maintenance is key to preventing future complications and keeping your riding experience enjoyable.