How to Fix a Bent Bicycle Rim unfolds a journey into the essential maintenance of one of the most critical components of your bicycle. Understanding the nuances of rim damage not only enhances your cycling experience but also ensures your safety on the road. This guide delves into the common causes of bent rims, the tools required for repair, and practical methods to restore your bicycle’s performance.

With knowledge of the signs indicating a bent rim and the necessary steps for repair, you can confidently tackle this common issue. Whether you’re a seasoned cyclist or a novice, this comprehensive overview will equip you with the skills needed to address rim problems effectively.

Understanding the Problem

A bent bicycle rim is a prevalent issue that can affect the performance and safety of your bike. Understanding the causes and signs of a bent rim is crucial for any cyclist, as it helps ensure a smooth and safe riding experience. Addressing this problem promptly can prevent further damage and enhance the lifespan of your bicycle.Various factors can contribute to the bending of a bicycle rim.

A common cause is impact from potholes or curbs while riding, which can lead to a sudden deformation of the rim shape. Additionally, improper tire pressure—either too low or too high—can increase the likelihood of bending. Excessive weight or stress on the wheel, whether from heavy loads or aggressive riding, can also lead to this issue.

Signs Indicating a Bent Rim

Recognizing the signs of a bent bicycle rim is essential for timely intervention. Riders should pay attention to the following indicators, which often signify that the rim is not in optimal condition:

- Wobbling Wheel: If the wheel exhibits noticeable wobbling when spun, it is a strong indication of a bent rim.

- Brake Noise: Unusual noises from the brakes, such as rubbing against the rim, can signal misalignment due to bending.

- Poor Handling: Difficulty in steering or maintaining a straight path can occur when the rim is bent, affecting overall bike handling.

- Visual Inspection: Visible signs of deformation or unevenness along the rim surface should not be overlooked.

Addressing a bent rim is important for several reasons. A bent rim can compromise the safety of the rider by making the bike less stable and more difficult to control. Moreover, neglecting this issue can lead to further damage, potentially resulting in a costly replacement of the wheel or other components. Timely repair not only enhances the safety and performance of the bicycle but also prolongs its lifespan and ensures an enjoyable riding experience.

“A bicycle rim that is not true poses a risk, not just to your ride, but also to your safety.”

Tools and Materials Needed

When it comes to fixing a bent bicycle rim, having the right tools and materials is essential for a successful repair. The following sections will Artikel the necessary tools and optional equipment that can assist in the process, as well as the materials needed for an effective repair.

Essential Tools for Rim Repair

To effectively repair a bent rim, certain tools are indispensable. The following list includes the primary tools required:

- Spoke Wrench: This tool is crucial for adjusting the tension of the spokes, which helps to realign a bent rim.

- Bike Stand: A stable bike stand provides support while you work on the wheel, making it easier to access the rim.

- Rubber Mallet: A rubber mallet is useful for gently tapping the rim back into shape without causing further damage.

- Tire Lever: This tool assists in removing the tire from the rim, which is often necessary for a proper repair.

- Ruler or Caliper: For measuring the extent of the bend and ensuring precise adjustments.

Optional Tools That Can Assist

While the essential tools are necessary for the repair process, there are optional tools that can enhance efficiency and ease. These include:

- Truing Stand: A truing stand provides a more accurate way to align the rim and is especially useful for professional repairs.

- Heat Gun: A heat gun can help soften certain materials, making it easier to reshape the rim.

- Chain Tool: If the rim is severely bent and causes chain misalignment, a chain tool might be necessary for adjustments.

Materials Needed for Repair

In addition to tools, specific materials are required to ensure a successful repair. Below is a comprehensive list of the materials needed for fixing a bent bicycle rim:

- Electrical Tape: Useful for temporarily securing any loose components during the repair.

- Spare Spokes: In case any spokes are damaged during the process, having spare spokes on hand is essential.

- Brake Pads: New brake pads may be necessary if the old ones are worn and need replacement due to the rim’s adjustment.

- Lubricant: A suitable lubricant can help in the smooth operation of the spokes and brakes after repair.

Assessing the Damage

Assessing the damage to a bent bicycle rim is a crucial step in determining the appropriate course of action for repair or replacement. Proper inspection not only helps in identifying the extent of the damage but also ensures the safety and performance of the bicycle once it is back in operation. Inspecting the rim for bends and dents involves a careful visual and tactile examination.

Begin by removing the wheel from the bicycle and placing it on a stable surface. Rotate the wheel slowly, looking for irregularities in the rim’s shape. A bent rim may appear wobbly or uneven as it spins. Using your hands, run along the rim to feel for any noticeable bumps or dips. If available, a truing stand can provide a more precise evaluation by allowing you to see how much the rim deviates from a straight line.

Determining Repairability

Determining whether a rim is repairable or needs replacement depends on several criteria related to the extent of the damage. The following factors are essential to consider:

Severity of the Bend

A minor bend might be straightened with proper tools, while severe bends often compromise the rim’s integrity.

Material of the Rim

Aluminum rims are generally easier to repair than carbon fiber rims, which are more prone to catastrophic failure if damaged.

Presence of Dents or Cracks

Any dent or crack can significantly weaken the rim. If there are cracks, replacement is usually the safest option.

Wheel Integrity and Age

Older wheels or those with multiple previous repairs may not be worth fixing due to potential hidden weaknesses.

It is essential to prioritize safety when assessing rim damage. If in doubt, consulting a professional is recommended.

The criteria for evaluating the severity of rim damage can be summarized as follows:

1. Visual Inspection

Look for noticeable bends, cracks, or dents.

2. Tactile Inspection

Run your fingers along the rim to feel for any irregularities.

3. Measurement

Use a ruler or caliper to measure deviations from a straight line.

4. Test Ride

After adjustments, a quick test ride can help identify if the rim is functioning properly.By carefully assessing the damage and considering these criteria, you can make an informed decision on whether to repair or replace the bent bicycle rim.

Methods for Fixing a Bent Rim

When dealing with a bent bicycle rim, several methods can be employed to restore it to its original shape. Each method has its own set of techniques and tools that can be utilized based on the severity of the bend and the experience of the individual performing the repair. Understanding these methods is essential for anyone looking to maintain their bicycle in optimal condition.Straightening a bent rim can often be accomplished using a variety of techniques, including the use of a truing stand, manual adjustments with a rubber mallet, or applying heat.

Each method offers distinct advantages and may be more suitable depending on the specific circumstances surrounding the damage.

Truing Stand Method

The truing stand is an invaluable tool for accurately assessing and correcting the alignment of a bicycle rim. This method provides precision and control, ensuring that the rim is adjusted to a straight position without causing further damage. The process involves several key steps:

1. Preparation

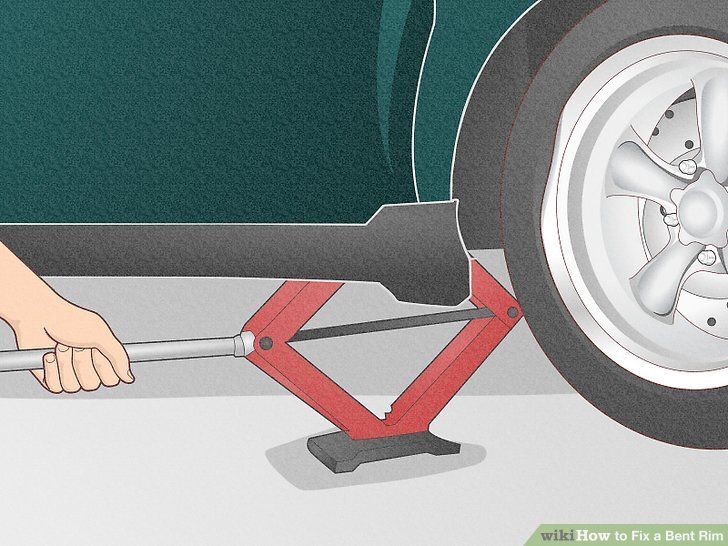

Begin by removing the wheel from the bicycle and placing it securely in the truing stand. Ensure the stand is stable and that the rim is centered between the two arms.

2. Assessment

Spin the wheel slowly while observing the rim’s alignment. Look for any high or low spots, which indicate where the rim is bent. Mark these areas with a pencil or small piece of tape for reference.

3. Adjustment

For a high spot, loosen the spokes on either side of the area slightly to allow the rim to move downwards.

For a low spot, tighten the spokes adjacent to the bend to pull the rim upwards.

Make small adjustments, rechecking the alignment after each modification to avoid over-correcting.

4. Final Check

Continue to spin the wheel and assess the adjustments until the rim runs true, maintaining a uniform distance from the truing stand arms on both sides.

5. Reinstallation

Once satisfied with the alignment, reinstall the wheel on the bicycle and check for proper brake clearance and overall alignment with the frame.

Alternative Methods

In addition to the truing stand method, there are alternative techniques available for straightening a bent rim. These methods can be particularly useful when a truing stand is unavailable or when dealing with minor bends.

Rubber Mallet Technique

This method is effective for minor bends and requires care to avoid damaging the rim.

Place the wheel on a stable surface with the bent area facing upward.

Gently tap the bent section with a rubber mallet to gradually straighten the rim.

Always check the rim’s alignment as you work, ensuring that excessive force is not applied.

Heat Application Method

This technique can help in bending the metal back into shape without cracking.

Use a heat gun to gently warm the bent area of the rim.

Once the metal becomes slightly malleable, apply pressure to reshape it back to its original contour.

Allow the rim to cool naturally to harden in its corrected position.

These methods are practical for different scenarios and can help maintain the integrity and performance of the bicycle rim. Always remember that careful assessment and gradual adjustments are crucial to successfully fixing a bent rim without causing further damage.

Step-by-Step Repair Guide

To successfully repair a bent bicycle rim, following a systematic approach is essential. The truing method is a widely recognized technique that can restore the rim’s original shape, ensuring a smooth and balanced ride. This guide Artikels the detailed steps required to effectively fix a bent rim while utilizing hand tools for a DIY repair, alongside important safety precautions.

Preparation for the Repair

Before commencing the repair, it is crucial to prepare adequately. Gather the necessary tools and materials, as well as ensure a safe working environment. The essential tools include a spoke wrench, rim truing stand (if available), and a tire lever.

- Spoke Wrench: This tool is used to adjust the tension of the spokes, which is critical in straightening the rim.

- Rim Truing Stand: While not mandatory, this tool provides a stable platform for assessing and correcting the wheel’s alignment.

- Tire Lever: Sometimes needed to remove the tire from the rim for an unobstructed view.

Assessing the Damage

Before beginning the truing process, it is vital to assess the extent of the damage to the rim. This assessment allows for a targeted approach to the repair.

- Spin the Wheel: Place the wheel in the truing stand and spin it to identify wobbles or high and low spots.

- Mark the Bent Area: Use a marker or chalk to indicate areas of noticeable deviation from the true line.

Executing the Truing Process

Once the damage is assessed, you can proceed with the truing process. Follow these steps to effectively fix the bent rim.

- Remove the Tire: If necessary, use the tire lever to remove the tire from the rim for better access.

- Identify High and Low Points: While spinning the wheel, locate the high and low spots indicated during the assessment phase.

- Tightening Spokes: For a high spot, tighten the spokes on the side opposite the bend using the spoke wrench. This action pulls the rim back into alignment.

- Loosening Spokes: Conversely, for a low spot, loosen the spokes on the same side as the bend to allow the rim to be pushed back into alignment.

- Check Alignment Constantly: After making adjustments, continuously spin the wheel to check for improvements and repeat the adjustments as necessary.

Safety Precautions

Maintaining safety throughout the repair process is crucial to avoid injuries and ensure a successful outcome. Consider the following precautions:

- Wear Safety Glasses: Protect your eyes from any debris that may dislodge during the repair.

- Work in a Well-Lit Area: Good lighting helps in accurately assessing the rim’s condition and making adjustments.

- Handle Tools with Care: Ensure that all tools are in good condition and used as intended to prevent accidents.

Always prioritize safety while working on your bicycle to ensure a smooth and injury-free repair process.

Maintenance Tips to Prevent Future Bending

Regular maintenance and inspection of your bicycle rims are crucial for ensuring a safe and enjoyable riding experience. By proactively addressing potential issues and practicing good riding habits, you can prevent damaging bends and keep your bicycle performing optimally. The following tips will help you maintain your rims and reduce the risk of future bending.

Regular Rim Inspections and Maintenance

Conducting periodic inspections of your bicycle rims is essential for identifying any signs of wear or damage before they lead to more serious issues. Regularly checking for abnormalities in the rim’s shape, material fatigue, or corrosion can significantly extend the lifespan of your wheels. To effectively maintain your rims, consider the following practices:

- Inspect the rims for cracks, dents, or severe scratches, especially after rides on rough terrain.

- Check the spoke tension regularly; loose spokes can contribute to rim deformation.

- Clean the rims frequently to prevent the buildup of dirt and debris that can lead to corrosion.

- Ensure brake pads are properly aligned and not making contact with the rim when not in use.

Avoiding Rim Damage While Riding

Practicing safe riding techniques is pivotal in preventing rim damage. Pay attention to the surfaces you ride on and adjust your riding style to minimize impact on your wheels.Consider the following strategies to avoid damaging your rims:

- Avoid riding over potholes, curbs, and other obstacles that can cause sudden impacts.

- Use caution when riding downhill or on uneven surfaces, which can increase the risk of bending a rim.

- Maintain appropriate tire pressure as per the manufacturer’s specifications to absorb shocks effectively.

- Choose suitable tires designed for the terrain you are riding on, which can cushion impacts better.

Safely Transporting Bicycles to Prevent Rim Bends

Transporting your bicycle requires careful handling to avoid any potential damage to the rims. Whether you are placing it on a bike rack or in your vehicle, implementing safety measures is essential.To ensure safe transportation of your bicycle, follow these recommendations:

- Use a quality bike rack that supports the frame and wheels without putting pressure on the rims.

- Consider removing the front wheel while transporting to reduce the risk of damage.

- Secure the bicycle with proper straps to prevent movement during transportation.

- If placing the bicycle inside a vehicle, ensure it is stable and cushioned to avoid impacts with other objects.

“Preventive maintenance is the key to prolonging the life of your bicycle rims and ensuring a safe ride.”

Seeking Professional Help

When it comes to bicycle maintenance and repairs, not every issue can be resolved with DIY methods. Some situations necessitate the expertise of a professional bike mechanic, especially when dealing with more complex damage to a rim. Understanding when to seek professional help can save both time and money in the long run, ensuring that your bicycle remains in optimal condition for safe riding.Professional repair is essential in various scenarios, particularly when the damage appears to be beyond simple bending or when structural integrity is compromised.

Signs that indicate the need for professional intervention include significant cracks, sharp bends that cannot be corrected by hand, or if the wheel is wobbling excessively even after attempts at adjustment. Each of these conditions can affect not only the performance of the bicycle but also the safety of the rider.

Choosing a Reputable Bike Shop

Selecting a trustworthy bike shop for rim repairs is crucial to ensure quality service. Here are several key factors to consider when choosing a bike shop:

1. Experience and Expertise

Look for shops that have seasoned mechanics with experience in wheel repairs. Their knowledge can greatly influence the outcome of the repair.

2. Customer Reviews

Reading reviews and testimonials from previous customers can provide insight into the shop’s reputation and service quality. Look for consistent positive feedback regarding rim repairs.

3. Certifications

A shop that employs certified bike mechanics often indicates a commitment to quality and professionalism. Certifications can also guarantee that the staff is knowledgeable about the latest repair techniques and standards.

4. Warranty on Repairs

Trustworthy bike shops often provide a warranty for their work, indicating confidence in the quality of their repairs. This assurance can be vital should any issues arise after the service.

“A skilled mechanic can identify not just the visible issues, but also underlying problems that may cause further complications.”

Costs of Professional Rim Repair

Understanding the potential costs associated with professional rim repair is important for budgeting purposes. Factors influencing the cost may include the extent of damage, the type of bicycle, and the labor rates of the shop.

Minor Repairs

These may range from $20 to $50, typically involving simple adjustments or minor straightening of the rim.

Moderate Repairs

Costs can rise to between $50 and $100 for more extensive work where parts of the rim may need replacement or more complex straightening techniques are utilized.

Severe Damage

In cases where the rim is irreparably bent or cracked, prices can exceed $100, especially if a complete wheel replacement is necessary.It’s advisable to obtain estimates from multiple bike shops to ensure you are receiving a fair price. Some shops may offer diagnostic fees that can be applied towards repair costs if you choose to proceed with the service.

“Investing in proper repairs can extend the life of your bicycle and enhance your riding experience.”

Conclusion

In conclusion, fixing a bent bicycle rim is not just about restoring your ride; it’s about embracing the joys of cycling with confidence and safety. By following the Artikeld steps and implementing regular maintenance practices, you can extend the life of your rims and enhance your overall cycling experience. Remember, when in doubt, seeking professional help ensures that your bicycle remains in optimal condition for all your adventures ahead.