How to Use a Torque Wrench on Your Bicycle is an essential guide that invites cyclists of all skill levels to delve into the critical practice of maintaining their bicycles with precision. Proper torque application ensures the longevity and safety of bicycle components, making it a vital skill for every cyclist. This guide will explore the nuances of torque wrenches, including their types, usage, and the significance of adhering to specified torque settings, ultimately enhancing your riding experience.

As we navigate through the intricacies of using a torque wrench, we will illuminate the importance of understanding torque specifications, preparing your bicycle for adjustments, and avoiding common pitfalls. Moreover, we will provide practical applications and resources to further enrich your knowledge in bicycle maintenance, ensuring you can confidently tackle this essential task with ease.

Introduction to Torque Wrenches

A torque wrench is an essential tool in bicycle maintenance, designed to apply a specific amount of torque to fasteners, such as bolts and nuts. This precision ensures that components are secured optimally, preventing both under-tightening, which can lead to parts loosening during use, and over-tightening, which may cause damage to the bicycle frame or components. Understanding how to use a torque wrench correctly can greatly enhance the longevity and safety of your bicycle.Proper torque settings are critical in maintaining the integrity of bicycle components, including the handlebars, seat post, and wheel hubs.

Each part has a specific torque specification that must be adhered to for optimal performance. For instance, carbon components are particularly sensitive to torque settings, as excessive force can lead to catastrophic failures. By utilizing a torque wrench, cyclists can ensure that all parts are tightened according to manufacturer specifications, which is crucial for safety and performance.

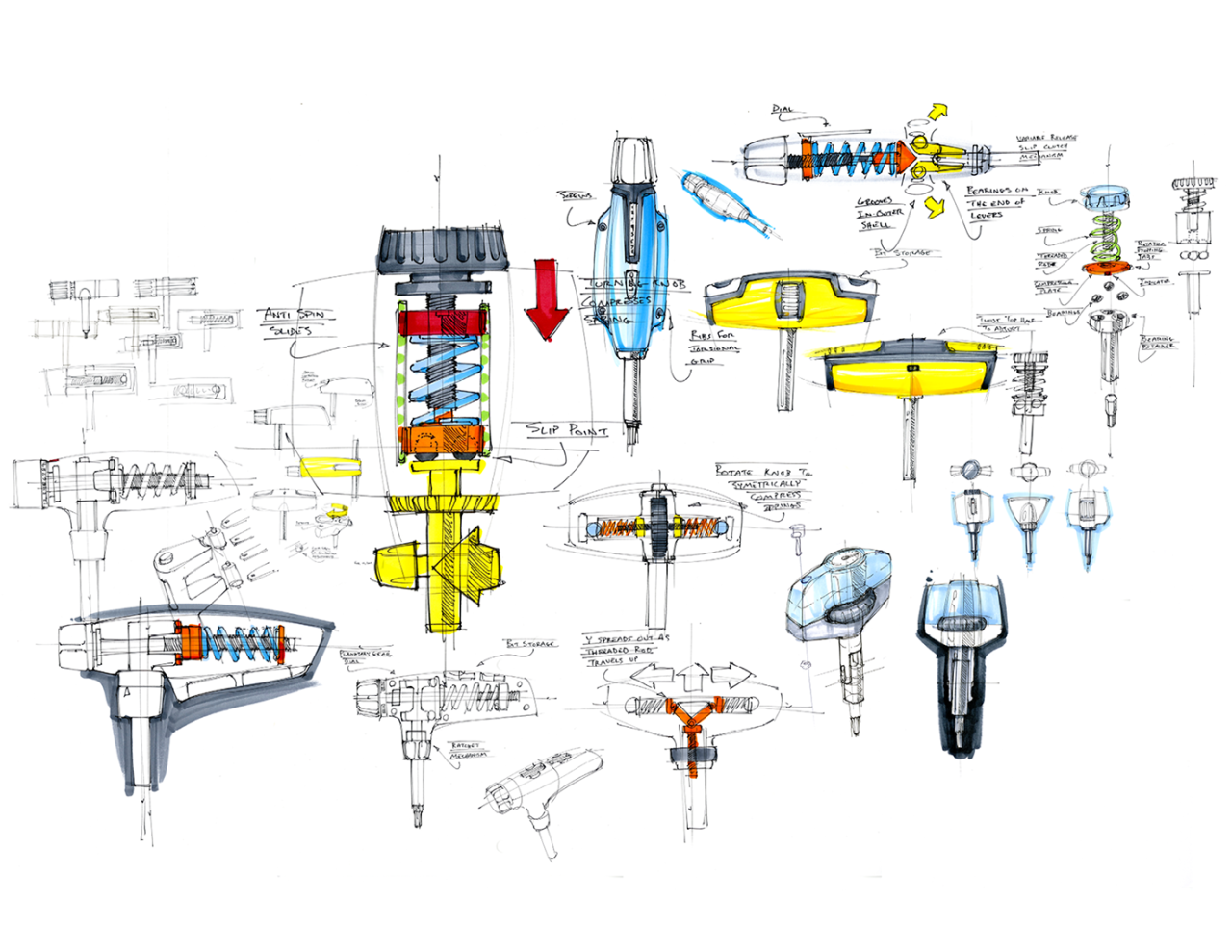

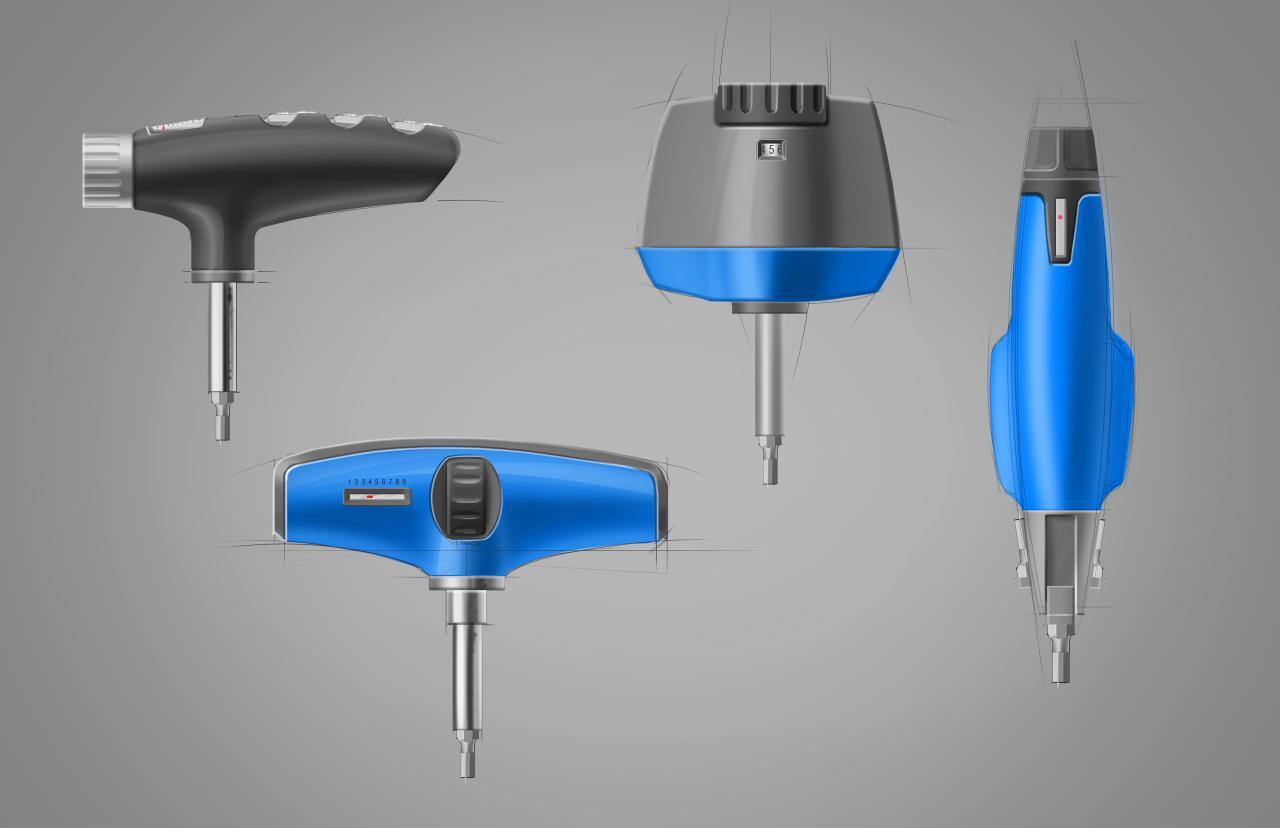

Types of Torque Wrenches for Cyclists

There are several types of torque wrenches available that cater to the needs of cyclists. Understanding these options will help you choose the right tool for your maintenance tasks.

- Click Torque Wrench: This type indicates when the preset torque level has been reached through an audible “click” sound. It is user-friendly and ideal for those who require precise torque settings without extensive experience.

- Beam Torque Wrench: A traditional design that uses a scale and a moving beam to indicate torque. While it may require more attention to detail, it is often more affordable and reliable for those familiar with torque settings.

- Electronic Torque Wrench: Equipped with digital displays, these wrenches provide electronic feedback and can store torque settings for various components. They are excellent for technicians who need to keep track of multiple specifications.

- Adjustable Torque Wrench: This allows users to set and adjust the torque level for different components, making it versatile for various maintenance tasks on the bicycle.

Choosing the appropriate torque wrench not only enhances the maintenance experience but also ensures that your bicycle operates safely and efficiently during rides. Each type has its unique advantages, so selecting the right one can be crucial depending on your specific cycling needs and the complexity of your bicycle’s components.

Understanding Torque Specifications

Proper torque specifications are critical for maintaining the safety and performance of your bicycle. Each component on your bike is designed to operate within specific torque limits to ensure optimal functionality and prevent damage. Understanding these specifications helps you avoid common mistakes that can lead to compromised safety or component failure. Torque specifications can generally be found in the manufacturer’s documentation for your bicycle or its components.

Additionally, many online resources and bicycle repair manuals provide valuable information for various bike parts. Familiarizing yourself with these specifications is essential for any cyclist who performs maintenance or repairs.

Common Torque Specifications for Bicycle Parts

The following list Artikels typical torque specifications for various bicycle components. Adhering to these specifications ensures that each part is secured correctly without risk of damage:

- Handlebar Stem: 5-8 Nm

- Seatpost Clamp: 5-7 Nm

- Brake Calipers: 6-8 Nm

- Crankset: 30-50 Nm (varies by design)

- Bottom Bracket: 35-50 Nm (varies by type)

- Disc Brake Rotors: 6-8 Nm

- Derailleur Hanger: 5-6 Nm

It is crucial to reference the specific torque values for your bicycle model, as these can vary by manufacturer and component design.

Locating Torque Specifications

Finding the correct torque specifications for your bicycle components involves consulting several resources. The most reliable sources include:

- Owner’s Manual: Most bicycles come with an owner’s manual that includes torque settings.

- Manufacturer’s Website: Visit the official website of the component manufacturer for detailed specifications and guidelines.

- Bicycle Repair Manuals: Comprehensive repair manuals often list torque specifications alongside installation instructions.

- Online Forums: Cycling forums and community websites can provide practical insights and shared experiences about torque settings.

Utilizing these resources ensures that you are working with the most accurate information available.

Consequences of Over-Torquing or Under-Torquing

Improper torque application can lead to severe consequences for bicycle components. Over-torquing may strip threads, crack carbon fiber parts, or cause misalignment, leading to poor performance or safety hazards. Conversely, under-torquing can result in loose components that may shift or detach during use, posing a significant risk to the rider.

“Ensuring that every component is tightened to its specified torque value is essential for the longevity and safety of your bicycle.”

Regular checks and adherence to torque specifications can prevent these issues, ensuring a safer and more enjoyable riding experience. Always utilize a calibrated torque wrench to maintain accuracy and precision in your adjustments.

Preparing to Use a Torque Wrench

Before utilizing a torque wrench on your bicycle, it is essential to gather the necessary materials and prepare both the bike and your workspace thoroughly. Proper preparation ensures accurate torque adjustments and promotes safety during the process.The materials needed for effectively using a torque wrench on a bicycle include the following items. Gathering these tools beforehand will streamline your workflow and minimize interruptions during the task.

Materials Needed

The following items are crucial for successfully using a torque wrench on your bicycle:

- Torque wrench: Ensure it is compatible with the torque specifications of your bicycle components.

- Socket or bit set: Depending on the type of fasteners your bicycle uses, appropriate sockets or bits are necessary.

- Bike maintenance stand: A stable stand will hold your bicycle securely while you work.

- Cleaning materials: Wipes or a degreaser can be useful for cleaning the components before adjustments.

- Safety goggles: Protect your eyes while working on the bicycle.

- Gloves: Use gloves to ensure a better grip and protect your hands from grease and dirt.

Prior to making torque adjustments, it is vital to ensure that your bicycle is safely prepared. This preparation involves setting up your bike appropriately to facilitate effective torque applications.

Steps to Safely Prepare a Bicycle

To ensure the bicycle is ready for torque adjustments, follow these steps:

- Position the bike on a maintenance stand: A stable platform will keep the bike upright and make it easier to access various components.

- Inspect the components: Look for any signs of wear or damage that might affect your adjustments.

- Clean the fasteners: Use cleaning materials to ensure that the areas around the fasteners are free of dirt and debris.

- Identify torque specifications: Refer to the manufacturer’s documentation to confirm the correct torque settings for each component.

- Calibrate the torque wrench: Ensure that the torque wrench is set to the correct torque value before beginning adjustments.

Setting up your workspace is equally important for maintaining focus and ensuring safety while using a torque wrench. A well-organized area minimizes distractions and enhances efficiency.

Workspace Setup Checklist

A systematic approach to organizing your workstation can significantly impact your productivity. Consider the following checklist for an optimal workspace setup:

- Clear the workspace of unnecessary items to create a safe environment.

- Have all required materials within easy reach to avoid interruptions.

- Ensure adequate lighting to enhance visibility during the adjustment process.

- Use a solid table or a workbench that can safely hold the weight of the bicycle.

- Keep a torque specification chart available for quick reference.

- Have a notebook or device ready to take notes on any adjustments made.

Step-by-Step Guide on Using a Torque Wrench

Using a torque wrench correctly is essential for ensuring that bicycle components are secured to the manufacturer’s specified torque settings. This practice not only enhances the safety and performance of the bicycle but also prolongs the life of its components. The following step-by-step guide will provide clarity on the procedure for using a torque wrench effectively.

Adjusting the Torque Wrench to the Desired Setting

Prior to using the torque wrench, it is necessary to set it to the required torque specification for the particular bicycle component. This ensures that the fasteners are tightened to the proper level, avoiding damage or malfunction.

1. Locate the Required Torque Specification

Refer to the bicycle manufacturer’s manual or component specifications to determine the appropriate torque setting, typically measured in Newton-meters (Nm) or foot-pounds (ft-lb).

2. Unlock the Torque Wrench

If the torque wrench has a locking mechanism, unlock it by turning the handle or pressing the release button.

3. Adjust the Setting

Rotate the handle or dial to set the torque to the desired value. For example, if the specification indicates 5 Nm, turn the dial precisely to that measurement.

4. Lock the Setting

Once the desired torque is set, lock the torque wrench again to maintain the setting during use. This prevents any accidental changes while tightening.

Applying Torque to a Bicycle Component

Proper technique when applying torque is vital to achieving a secure fit without damaging the component. Follow these steps:

1. Position the Torque Wrench

Align the torque wrench’s drive socket with the bolt or fastener you intend to tighten. Ensure that the wrench is perpendicular to the bolt for accurate torque application.

2. Grip the Handle Firmly

Hold the wrench by its handle, ensuring your grip is firm but not overly forceful. This allows for a controlled application of torque.

3. Begin Slowly

Start applying torque slowly, focusing on a smooth and steady pressure. It is crucial to avoid sudden jerking motions that may lead to inaccurate readings.

4. Listen for the Click

Most torque wrenches are designed to emit a click sound when the set torque level is reached. Pay attention to this audible cue, signaling that the desired torque has been applied.

5. Release Pressure

After hearing the click, stop applying force immediately. Continuing to apply pressure may exceed the torque specification and damage the component.

6. Recheck Tightness

If necessary, it can be prudent to recheck the tightness using the torque wrench to confirm that the fastener is secure.

“Using a torque wrench correctly ensures the longevity and performance of your bicycle components.”

Following these steps will provide the confidence needed to use a torque wrench effectively while maintaining the integrity of your bicycle. By adhering to the specified torque settings, you will ensure safe and optimal performance on every ride.

Common Mistakes to Avoid

Using a torque wrench is essential for proper bike maintenance, yet several common mistakes can lead to improper torque application, potentially resulting in damage to components or safety hazards. Recognizing these errors can help cyclists achieve optimal performance and longevity from their bicycles.One of the most frequent mistakes is failing to zero the torque wrench before use. This essential step ensures the wrench is calibrated correctly, preventing the application of incorrect torque values.

Additionally, another common error is applying torque in a continuous motion rather than in a smooth, controlled manner, which is crucial for accurate results. Recognizing when a mistake has been made can be challenging; however, there are indicators that can help. For instance, if a bolt feels unusually loose or tight after torque application, it’s likely an error occurred.

Common Errors During Torque Application

Understanding and identifying the following errors can enhance the effectiveness of using a torque wrench on your bicycle:

- Inadequate Familiarization with the Torque Wrench: Not fully understanding the specific torque settings for various components can lead to over-tightening or under-tightening.

- Incorrect Torque Direction: Always ensure that the torque wrench is used in the proper direction. Using it in reverse can cause significant damage.

- Neglecting to Clean the Bolt Threads: Dirt or grime on the bolt threads can cause inaccurate torque readings. It’s essential to clean the threads before applying torque.

- Failure to Use a Torque Wrench Appropriately: Using a torque wrench as a breaker bar to loosen bolts can damage the tool, leading to inaccurate torque readings in the future.

- Ignoring Manufacturer Specifications: Each component has specific torque specifications. Failing to adhere to these can compromise the integrity of parts.

Recognizing these errors is crucial for maintaining accuracy and safety while working on your bicycle. Preventative measures can include regular training on torque applications and keeping a detailed log of torque settings used on your bike components. In addition, always cross-reference torque specifications with the manufacturer’s guidelines, ensuring that both the wrench and the component are in good condition to prevent mishaps.

“Proper torque application is not just about tightness; it ensures safety and reliability in your bicycle’s performance.”

Utilizing these insights will help cyclists achieve successful maintenance, extending the life and performance of their bicycles significantly.

Maintenance of Torque Wrenches

Maintaining a torque wrench is essential for ensuring accurate and reliable measurements, which are crucial for the safety and performance of your bicycle. Regular maintenance not only extends the tool’s lifespan but also helps in achieving consistent results during its use. Regular calibration of a torque wrench is vital as it guarantees the tool functions within its specified accuracy range.

Over time, the internal mechanisms may wear down or become misaligned, leading to inaccurate torque readings. Calibration should be performed at least once a year or after significant use, especially if the wrench has been subjected to extreme conditions or has been dropped.

Cleaning and Storing Torque Wrenches

Proper cleaning and storage practices significantly enhance the longevity and performance of a torque wrench. After each use, it is important to clean the tool to remove dirt, grease, and any debris that could interfere with its mechanism. To maintain a torque wrench effectively, adhere to the following guidelines:

- Wipe the handle and shaft with a soft, dry cloth after each use.

- Use a mild cleaning solution for any stubborn grime, ensuring no moisture remains afterward.

- Store the torque wrench in a protective case to prevent damage from dust or physical impact.

- Avoid leaving the torque wrench under tension; always reset it to its lowest setting when not in use to maintain calibration integrity.

Signs of Torque Wrench Servicing Needs

Awareness of the signs indicating that a torque wrench requires servicing or replacement is crucial to ensure its effectiveness. Various indicators may suggest maintenance is necessary. Key signs to watch for include:

- Inconsistent torque readings, where the same setting yields varying results.

- Physical damage, such as cracks or bends in the wrench’s body or head.

- Difficulty in adjusting the torque settings or a loose feel during use.

- Unusual noises when the wrench is operated, indicating potential internal issues.

Keeping these signs in mind can prevent potential mishaps and ensure that your bicycle is always in optimal condition.

Practical Applications and Scenarios

Using a torque wrench on your bicycle is not merely a best practice; it is essential for the maintenance and safety of your ride. Whether you are a casual cyclist or a serious racer, understanding when and how to apply torque specifications can significantly enhance the performance and longevity of your bicycle components. The following scenarios highlight critical applications of torque wrenches in cycling.

Critical Scenarios for Torque Wrench Usage

There are specific situations where the use of a torque wrench is indispensable. These scenarios include assembling new bikes, performing regular maintenance, or making adjustments after a fall or crash. Here are several examples:

- Handlebar Installation: Proper torque settings ensure that handlebars are securely fastened. Over-tightening can damage components, while under-tightening may lead to failure during rides.

- Seat Post Adjustment: Correctly torquing the seat post prevents slippage during rides. This is especially important for riders who frequently adjust their seat height for different terrains.

- Wheel Nut Tightening: Ensuring that wheel nuts are tightened to the manufacturer’s specifications can prevent accidents caused by wheels coming loose while riding.

- Brake System Setup: Proper torque on brake calipers and levers ensures optimal performance and responsiveness, which is crucial for safety.

Handling Specific Components

It is essential to follow specific torque specifications when handling components such as handlebars, seat posts, and wheel nuts. Below are guidelines for these components:

- Handlebars: Typically, the torque should be set between 5 to 8 Nm. This ensures a secure fit without damaging the components.

- Seat Posts: For most seat posts, a torque setting of 4 to 6 Nm is recommended. This prevents slippage while allowing for adjustments as necessary.

- Wheel Nuts: Front wheel nuts generally require 10 to 12 Nm, while rear wheel nuts may need 12 to 15 Nm. These settings help prevent the wheels from loosening during high-speed rides.

Torque Specifications by Cycling Discipline

Understanding torque specifications for different cycling disciplines can help cyclists apply the correct settings based on their riding style. Below is a table of recommended torque specifications across various cycling disciplines:

| Component | Road Cycling (Nm) | Mountain Biking (Nm) | Hybrid Cycling (Nm) |

|---|---|---|---|

| Handlebars | 5 – 8 | 5 – 8 | 5 – 8 |

| Seat Post | 4 – 6 | 5 – 7 | 4 – 6 |

| Brake Calipers | 6 – 8 | 6 – 10 | 6 – 8 |

| Wheel Nuts | 10 – 12 | 12 – 15 | 10 – 12 |

“Proper torque application is crucial not only for performance but also for the safety of the cyclist.”

Additional Resources

Expanding your knowledge on bicycle maintenance and torque wrench usage is essential for any cyclist. Numerous resources are available to enhance your understanding and practical skills, which can lead to better performance and safety while riding. Below are recommended books, online tutorials, and community forums that can serve as valuable tools in your learning journey.

Books and Online Resources

A variety of literature exists that covers bicycle maintenance comprehensively, including specialized guides on using torque wrenches effectively. These resources not only provide foundational knowledge but also advanced techniques.

- The Essential Guide to Bicycle Maintenance by Tom Neale – This book covers all aspects of bicycle care, including torque specifications and the proper use of tools.

- Park Tool’s Big Blue Book of Bicycle Repair – A comprehensive resource filled with clear instructions and illustrations on bicycle repair and maintenance.

- Online platforms such as Bicycle Tutor and GCN (Global Cycling Network) offer detailed articles and tutorials on bicycle maintenance and the use of torque wrenches.

Videos and Tutorials

Visual aids can greatly enhance your understanding of how to use a torque wrench correctly. Numerous online videos demonstrate the step-by-step process and common pitfalls to avoid.

- GCN’s Torque Wrench Tutorial – A concise video that Artikels how to set and use a torque wrench effectively, illustrating both common mistakes and best practices.

- Park Tool’s YouTube Channel – Offers a series of videos focusing on various bicycle maintenance tasks, including torque settings for specific components.

- Global Cycling Network’s DIY Bike Repair Series – Provides practical demonstrations on using tools, including torque wrenches, in real-life scenarios.

Cyclist Communities and Forums

Engaging with fellow cyclists can provide invaluable insights and tips from experienced users. Forums and online communities serve as platforms for sharing knowledge and experiences regarding bicycle maintenance.

- BikeForums.net – A robust community where cyclists discuss maintenance tips, including the use of torque wrenches.

- Reddit’s r/bicycling – A popular forum where users can post questions and share advice on all aspects of cycling, including bike maintenance techniques.

- Facebook Groups – Many dedicated groups exist for bike enthusiasts, where members regularly share resources, experiences, and recommendations specifically related to maintenance and tool usage.

Final Wrap-Up

In conclusion, mastering the use of a torque wrench on your bicycle not only enhances your maintenance skills but also contributes to safer and more enjoyable rides. By understanding the correct torque settings and employing the right techniques, you can prevent damage to your bicycle components and ensure optimal performance. Remember that regular maintenance and calibration of your tools are just as crucial, allowing you to maintain your bicycle in peak condition for years to come.