How to Adjust Friction Shifters on a Vintage Bike is a detailed guide aimed at ensuring your cherished vintage bicycle performs optimally. Friction shifters, a hallmark of classic cycling, offer a unique connection between the rider and the machine. Understanding their mechanics and maintenance can enhance your cycling experience and preserve the bike’s integrity.

The evolution of friction shifters has played a pivotal role in the cycling world, providing riders with the ability to easily shift gears while riding. Unlike modern indexed systems, friction shifters rely on the rider’s skill and feel, making them an essential component of vintage bikes. This guide will walk you through the necessary adjustments and maintenance practices to keep your friction shifters functioning smoothly.

Introduction to Friction Shifters

Friction shifters are an integral component of vintage bicycles, allowing riders to change gears with a simple yet effective mechanism. Unlike modern indexed systems, friction shifters offer a versatile and user-friendly approach to gear shifting, making them a favorite among cycling enthusiasts who appreciate the classic design and functionality of older bike models. Understanding their function and importance can significantly enhance the cycling experience.Friction shifters operate on a straightforward principle: the rider manually adjusts the position of the derailleur by moving a lever, thereby changing the chain’s position along the gear cogs.

This design empowers cyclists to fine-tune their shifting according to terrain and personal preference. The history of friction shifters dates back to the early 20th century when they were first introduced as a reliable means of shifting gears on multi-speed bicycles. Over the decades, these shifters have evolved, with various designs enhancing their ergonomics and performance.

Differences Between Friction Shifters and Indexed Shifters

Friction shifters and indexed shifters differ fundamentally in their operation and user experience. Understanding these differences is crucial for selecting the right shifter for your bicycle. Friction shifters allow for continuous adjustment, enabling riders to find the perfect gear without being restricted to predefined notches. This flexibility is especially advantageous in varying conditions where precision shifting is required. In contrast, indexed shifters use a system of defined clicks or stops that correspond to specific gear positions, providing a more straightforward and, at times, more reliable shifting experience.The key distinctions can be summarized as follows:

- Shifting Mechanism: Friction shifters rely on the rider’s skill to find the right gear, while indexed shifters offer a set gear configuration with defined stops.

- Gear Compatibility: Friction shifters are more versatile, accommodating a broader range of gear ratios and setups, making them suitable for various bicycle configurations.

- User Experience: Cyclists accustomed to friction shifters often enjoy the tactile feedback and control they offer, whereas indexed shifters provide a more streamlined and user-friendly experience for those unfamiliar with manual adjustments.

“The essence of cycling lies in the harmony between rider and machine, and friction shifters epitomize this connection through their simplicity and adaptability.”

Embracing the characteristics of friction shifters can lead to a greater appreciation for vintage bikes and the craftsmanship that defines them. Their enduring presence in the cycling world serves as a testament to their effectiveness and the nostalgic allure they hold for many riders.

Tools Required for Adjusting Friction Shifters

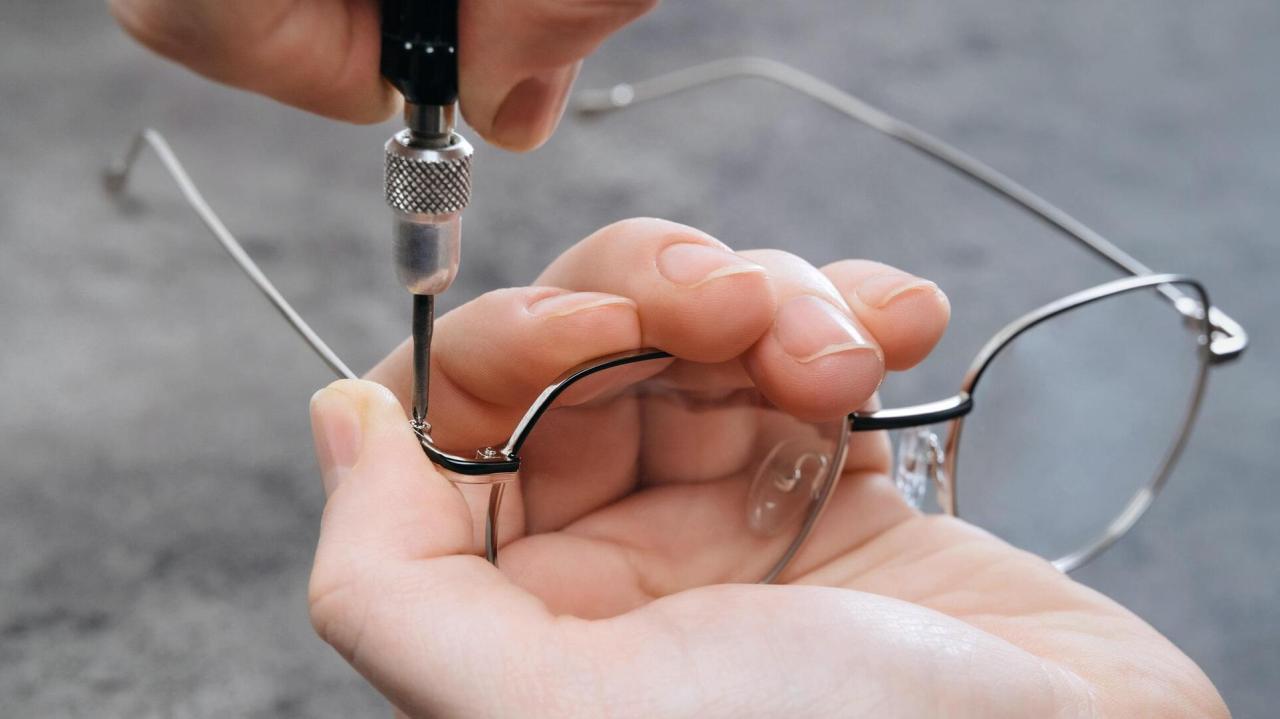

Adjusting friction shifters on vintage bikes requires a set of specific tools to ensure smooth operation and optimal performance. Having the right tools on hand can make the adjustment process efficient and effective, allowing for a seamless riding experience. Below is a detailed overview of the essential tools needed for this task.

Essential Bicycle Maintenance Tools

A comprehensive toolkit is vital for maintaining and adjusting various components of a bicycle, especially for vintage models. Below is a list of common tools every bike enthusiast should possess, including their specific uses in the context of friction shifter adjustment:

- Allen Wrenches: These are essential for tightening or loosening bolts on components such as shifters and derailleurs. A set with various sizes will accommodate most vintage bike fittings.

- Screwdrivers: A flathead and a Phillips screwdriver are necessary for adjusting screws on the shifter mechanism and securing cables.

- Bike Repair Stand: Utilizing a repair stand allows for easy access to the bike while making adjustments, ensuring a stable working environment.

- Chain Tool: This tool is used for removing and installing the chain, which can be necessary during adjustments of the shifter system.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage to vintage components from over-tightening.

In addition to these common tools, there are specific items that may enhance the adjustment process for vintage bikes.

Additional Tools for Vintage Bike Shifters

Vintage bike shifters may require specialized tools due to their unique designs and materials. Here are additional tools that could be beneficial:

- Cable Cutters: A good pair of cable cutters ensures clean cuts on shifter cables, which is crucial for optimal shifting performance.

- Adjustment Tool for Vintage Shifters: Some vintage shifters may have proprietary adjustment screws that require a specialized tool for precise tuning.

- Lubricants: High-quality bike-specific lubricants are essential for ensuring smooth operation of the shifter mechanisms, especially in older models prone to wear.

- Cleaning Brushes: Keeping the shifter and derailleur clean of dirt and grime will help maintain their functionality and longevity.

Utilizing the correct tools not only simplifies the adjustment process but also ensures that the integrity of the vintage bike is preserved throughout maintenance procedures.

Understanding the Mechanism of Friction Shifters

Friction shifters are an essential component of many vintage bicycles, allowing riders to change gears through a simple yet effective mechanism. Understanding their internal components and functioning is crucial for effective maintenance and adjustment. This section will explore the intricacies of friction shifters, comparing them to other shifting systems and addressing common issues that may arise over time.The internal components of friction shifters include a lever, a ratchet, and a cable housing.

The lever, typically mounted on the handlebars, allows the rider to manually adjust the gear settings by applying varying amounts of force. The ratchet acts as a guide for the cable, which connects the shifter to the derailleur, enabling the movement of the chain across the gears. Unlike indexed shifters, which rely on specific notches for precise gear changes, friction shifters operate on a more fluid mechanism, allowing for a greater degree of rider control.

Mechanics of Friction Shifting

Friction shifting works through a simple mechanical principle that stands in contrast to indexed systems. In friction shifters, the rider manually controls the tension in the cable, thereby moving the derailleur to the desired gear position. This is achieved through the following mechanisms:

- The lever’s position determines the tension on the cable. As the lever is pushed, the cable tightens, pulling the derailleur to shift the chain onto a different cog.

- Riders can fine-tune the shift by adjusting the lever, allowing for seamless transitions between gears, especially beneficial on varied terrain.

- This system provides a natural feel, giving riders the ability to shift at their own pace, which can be particularly advantageous in situations where rapid gear changes are not required.

Understanding the operational differences between friction and indexed shifters is essential. While indexed shifters provide a more straightforward, click-based system, friction shifters offer versatility and adaptability. This can be particularly appealing to avid cyclists who prefer the tactile feedback and enhanced control offered by friction systems.

Common Issues and Wear Patterns

Like any mechanical component, vintage friction shifters are susceptible to wear and tear over time. Recognizing common issues can aid in effective maintenance and prolong the lifespan of the shifters. Some prevalent wear patterns and problems include:

- Cable fraying or stretching: Over time, the cables can wear out, leading to poor shifting performance.

- Worn ratchet mechanism: The ratchet may become less effective with prolonged use, resulting in slippage during shifts.

- Dirt and grime buildup: Accumulation of debris can hinder the smooth operation of the shifter, requiring regular cleaning for optimum performance.

Addressing these issues promptly can prevent more significant complications, ensuring a smooth and enjoyable riding experience. Regular inspections and maintenance of friction shifters are recommended, as they not only enhance performance but also preserve the nostalgic charm of vintage bicycles.

Step-by-Step Guide to Adjusting Friction Shifters

The process of adjusting friction shifters can significantly enhance the performance of your vintage bike. A well-adjusted friction shifter ensures smoother gear transitions and can prolong the lifespan of your drivetrain components. The following guide Artikels a systematic approach to achieve optimal adjustments.Understanding the correct positioning of your shifter in relation to gear settings is crucial for successful adjustments. This guide presents a detailed procedure to help you navigate the adjustment process efficiently.

Adjustment Procedure for Friction Shifters

Preparation is essential before diving into the adjustment steps. Ensure that your bike is in a stable position, preferably on a bike stand or upside down, allowing accessibility to the shifters and derailleur. Below is a structured adjustment process:

- Inspect the Current Setup: Begin by examining the shifter for any visible damage or wear. Ensure the cable is not frayed and the housing is intact.

- Shift to the Middle Gear: Position the shifter in the middle gear setting. This position provides a neutral reference point for making adjustments.

- Loosen the Cable Tension: Use a 5mm Allen key to loosen the bolt securing the cable at the derailleur. This allows for free movement of the derailleur during adjustment.

- Align the Derailleur: With the bike on a stand, manually shift the derailleur to the middle chainring, ensuring it is directly aligned with the middle sprocket. Proper alignment is crucial for efficient gear changes.

- Adjust the Limit Screws: Check the limit screws on the derailleur to ensure they prevent the chain from overshifting. Typically, the ‘H’ (high) limit screw should restrict the derailleur from shifting onto the smallest sprocket, while the ‘L’ (low) limit screw should restrict it from shifting onto the largest sprocket. Adjust these screws as needed.

- Reattach the Cable: Once the derailleur is aligned and limit screws are set, reattach the cable to the derailleur. Ensure it is taut but not overly tight. A slight tension allows for smooth shifting.

- Test Shifting: Shift through all gears multiple times to ensure a smooth transition. Pay close attention to any skipping or hesitation in shifting. Adjust the cable tension if necessary by turning the barrel adjuster.

- Final Adjustments: Repeat the testing and adjustment process, if needed, until you achieve consistent and reliable shifting across all gears.

“A well-tuned friction shifter can significantly improve your cycling experience, providing precise control over gear changes.”

Following these steps will ensure that your friction shifters are properly adjusted, leading to an enjoyable and efficient ride on your vintage bike.

Common Problems and Troubleshooting

:max_bytes(150000):strip_icc()/how-to-adjust-cabinet-hinges-1822181-01-9518583bf0374f2a8d3b87cadd5fc25f.jpg)

Friction shifters, while offering a direct and intuitive way to change gears, can encounter various issues that hinder their performance. Understanding these common problems, their symptoms, and solutions is vital for maintaining the functionality of vintage bikes equipped with friction shifters. This section provides insights into typical issues and essential maintenance tips.

Common Issues with Friction Shifters

Friction shifters may present several common problems, which can affect their operation and the overall riding experience. Identifying these issues early can help in addressing them effectively. The following Artikels typical problems along with their symptoms:

- Slipping Gears: When the shifter fails to maintain position, leading to unexpected gear changes.

- Sticking Shifter: Difficulty in shifting due to a lack of lubrication or accumulation of dirt.

- Unresponsive Shifting: Lack of engagement when attempting to shift gears, often due to improper adjustment or wear.

- Misalignment: The shifter may not align correctly with the derailleur, causing ineffective shifting.

- Excessive Friction: Difficulty in moving the shifter, which can be caused by rust or dirt in the mechanism.

Solutions for Common Issues

Each of the problems identified can be addressed with specific solutions. The following sections detail practical fixes for each issue encountered with friction shifters.

- Slipping Gears: Ensure that the cables are properly tensioned and the shifter is securely fastened. Inspect for wear in the cable or housing, as replacements may be necessary.

- Sticking Shifter: Clean the shifter mechanism thoroughly and apply a suitable lubricant to ensure smooth operation. Regular cleaning can prevent buildup.

- Unresponsive Shifting: Check the cable for frays and ensure it is correctly threaded through the shifter. Adjust the tension as needed to improve engagement.

- Misalignment: Realign the derailleur and ensure that the shifter is in the correct position relative to the derailleur’s intended range.

- Excessive Friction: Inspect for rust or dirt in the shifter’s mechanism. Use a suitable cleaner to remove debris and lubricate to reduce friction.

Maintenance Tips for Friction Shifters

Regular maintenance plays a crucial role in enhancing the longevity and performance of friction shifters. Implementing preventive measures can significantly reduce the occurrence of issues. Consider the following tips for ongoing maintenance:

- Regular Cleaning: Periodically remove dirt and grime from the shifter and surrounding components. Use a soft brush or cloth for this task.

- Lubrication: Apply a light, appropriate lubricant to the shifter mechanism to ensure smooth operation. Avoid over-lubrication, as it may attract more dirt.

- Inspect Cables: Regularly check the condition of the shift cables and housing, replacing any frayed or damaged parts to maintain responsive shifting.

- Check Alignment: Ensure that the derailleur and shifter are properly aligned. Misalignment can lead to shifting inefficiencies and potential damage.

- Store Properly: When not in use, store the bike in a dry place to prevent rust and moisture accumulation on the shifters and cables.

“Regular maintenance ensures that vintage friction shifters perform optimally, providing a reliable and enjoyable cycling experience.”

Enhancing Performance of Friction Shifters

Improving the performance of friction shifters on vintage bikes is essential for achieving smooth and reliable gear transitions. With the right adjustments and maintenance practices, you can significantly boost the efficiency of your shifting system, thereby enhancing your overall riding experience.The performance of friction shifters is heavily influenced by various factors, including cable tension and the condition of the housing.

Proper cable tension ensures that the mechanism engages smoothly, while well-maintained housing allows for minimal friction, resulting in seamless shifts. Regular attention to these areas is vital for optimizing the functioning of your bike’s shifting system.

Cable Tension and Housing Condition

Maintaining optimal cable tension and ensuring the housing is in good condition play crucial roles in the shifting efficiency of friction shifters. The following points underline their importance:

Cable Tension

Proper tension allows the shifter to move the derailleur effectively, while too much slack can lead to missed shifts or difficulty in changing gears.

Housing Condition

Worn or damaged cable housing can create friction, impeding the movement of the cable and making shifts less precise. Regular inspections are essential to identify any signs of wear.To maintain friction shifters effectively, consider the following maintenance tips to keep them performing optimally:

- Ensure cables are lubricated regularly to reduce wear and friction.

- Inspect cable housing for cracks or wear and replace if necessary.

- Adjust cable tension using the barrel adjuster to fine-tune shifting performance.

- Keep the derailleur clean and free from debris to ensure smooth operation.

- Check the alignment of the derailleur to ensure it is correctly positioned relative to the cassette.

- Replace any frayed cables promptly to prevent shifting issues.

- Regularly test shifting performance after adjustments to confirm proper function.

By implementing these strategies, you can ensure that your vintage bike’s friction shifters operate at peak performance, providing you with reliable and efficient gear changes for many rides to come.

Comparing Friction Shifters with Modern Systems

/Adjust-Cabinet-Hinges-93246773-5751b7415f9b5892e8722a6b.jpg)

Friction shifters, once the standard for bicycle gearing, have long been compared to modern indexed shifting systems. Each has unique features that cater to different cycling preferences and riding styles. Understanding the advantages and disadvantages of friction shifters as opposed to modern indexed systems can aid in making informed choices for both vintage enthusiasts and contemporary cyclists alike.When comparing friction shifters with modern indexed systems, it is essential to consider their operational mechanics, user experience, and performance in various scenarios.

Friction shifters offer a more hands-on approach, allowing riders to shift gears with less reliance on precise calibration, while indexed systems provide ease of use and faster gear changes.

Advantages and Disadvantages

The benefits and drawbacks of friction shifters versus indexed systems vary based on riding conditions and personal preferences. Below are specific points highlighting the differences:

- Advantages of Friction Shifters:

- Greater adaptability in varying conditions: Friction shifters can be adjusted on the fly, enabling seamless gear transitions even if the derailleur is slightly misaligned.

- Durability: With fewer moving parts and a simpler mechanism, friction shifters often outlast indexed systems, especially in harsh weather or rugged terrains.

- Customizable user experience: Riders can fine-tune their shifting style, as friction shifters allow for a more personalized approach to gear changes.

- Disadvantages of Friction Shifters:

- Requires more skill and attention: Shifting with friction shifters demands a level of expertise that may overwhelm novice cyclists.

- Less precise compared to indexed systems: Riders may experience a less satisfying feel compared to the crisp clicks of modern gear changing mechanisms.

- Potentially slower shifting: In competitive situations, indexed systems can allow quicker gear changes, giving them an advantage over friction shifters.

Scenarios Favoring Friction Shifters

Friction shifters can outperform indexed shifters in specific situations where adaptability and durability are crucial. For instance:

- Touring and Long-Distance Rides: In varying terrains, friction shifters allow for easy adjustments that can accommodate sudden changes in the road or trail conditions.

- Older or Vintage Bikes: When restoring classic bicycles, maintaining the original componentry often means opting for friction shifters, which harmonize with the bike’s aesthetic and functionality.

- Inconsistent Maintenance Conditions: For cyclists who may not have regular access to bike maintenance, the reliability of friction shifters in diverse environments is often advantageous.

Cycling Experience with Friction Shifters

Riding a vintage bike equipped with friction shifters offers a unique experience compared to modern setups. The tactile feedback of manually shifting gears fosters a deeper connection between the cyclist and the bike. This engagement often leads to a more intentional riding style, as each gear change requires a conscious decision based on terrain and speed.Additionally, the simplicity of friction shifters can evoke a sense of nostalgia, transporting riders back to a more traditional era of cycling.

The absence of complex electronics or precision mechanisms can also mean less to worry about while on the road, allowing cyclists to focus on the joy of riding.In conclusion, while modern indexed systems provide ease and speed, friction shifters offer unique advantages that can enhance the cycling experience for those who appreciate the charm and craftsmanship of vintage bikes.

Conclusion and Best Practices

Maintaining and adjusting vintage friction shifters is vital for ensuring the longevity and performance of classic bicycles. Such bikes embody a rich history of cycling technology, and understanding how to care for them helps retain their charm and functionality. In this section, we will Artikel key best practices that every vintage bike enthusiast should consider.

Best Practices for Maintaining and Adjusting Vintage Friction Shifters

Regular maintenance and proper adjustments can greatly enhance the performance and lifespan of friction shifters. The following practices are recommended for optimal care:

- Regular Cleaning: Clean the shifters and cables periodically to remove dirt and grime. Use a soft cloth and a gentle degreaser to avoid damaging any components.

- Lubrication: Apply a suitable lubricant to the pivot points of the shifters. This helps ensure smooth operation and prevents corrosion.

- Check Cable Tension: Regularly assess the tension in the cables. Too much slack or excessive tension can affect shifting performance.

- Inspect for Wear: Frequently examine the shifter components for signs of wear or damage. Replace any worn items to maintain optimal performance.

- Follow Manufacturer Guidelines: Adhere to any specific recommendations provided by the manufacturer regarding maintenance and adjustments.

- Document Adjustments: Keep a log of any adjustments or repairs made to the shifters. This can be useful for future reference and troubleshooting.

Preserving vintage bike technology is significant as it allows enthusiasts to appreciate the ingenuity and craftsmanship of past eras. These bicycles not only offer a distinct riding experience but also connect us to cycling’s history. Engaging with vintage bike technology fosters a rich community of cyclists who share a passion for riding and restoring classic machines. Exploring resources such as online forums, local clubs, and vintage bike shows can enhance your knowledge and provide you with connections to fellow enthusiasts.

These communities often share valuable tips, techniques, and even rare parts necessary for maintaining vintage bikes. In conclusion, embracing the care of friction shifters not only ensures a better riding experience but also celebrates the history and artistry of vintage bicycles.

Final Wrap-Up

In conclusion, mastering the adjustment and maintenance of friction shifters on vintage bikes not only enhances your riding experience but also honors the rich history of cycling technology. By following best practices and understanding common issues, you can ensure that your vintage bike remains a reliable companion on your journeys. We encourage you to connect with fellow enthusiasts and share your experiences, fostering a community that celebrates the art of vintage cycling.