How to Fix a Leaky Schrader Valve sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. Schrader valves play a vital role in various applications, from bicycle tires to automotive systems, ensuring a secure seal that prevents air leaks. However, issues such as leaks can arise, necessitating a thorough understanding of their components and functions, as well as effective repair techniques.

This guide will walk you through diagnosing leaky Schrader valves, the essential tools and materials required for repair, and detailed step-by-step procedures to ensure a successful fix. By maintaining your Schrader valves properly and knowing when to seek professional help, you can ensure their longevity and reliability in your applications.

Understanding Schrader Valves

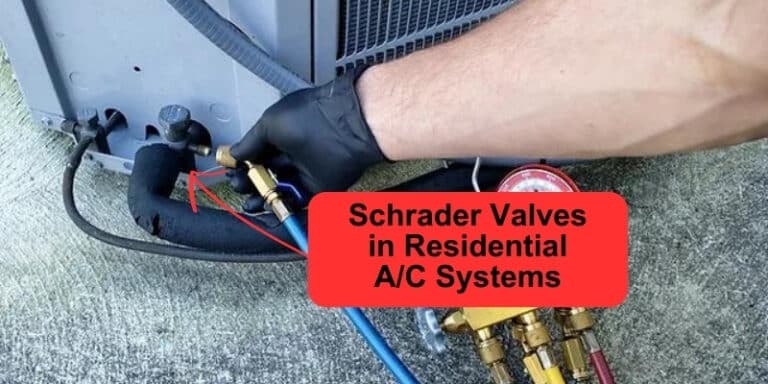

Schrader valves are essential components used in a variety of applications, particularly in the automotive and bicycle industries. Their primary purpose is to manage the inflation and deflation of pressurized systems, ensuring that air or fluid can be added or released as needed. A firm grasp of their function and common issues is crucial for effective maintenance and repair.Schrader valves are typically found on tires, HVAC systems, and various inflatables.

They function by allowing air or gas to enter while preventing it from escaping. This is accomplished through a spring-loaded mechanism that seals the valve when not in use. However, like any mechanical device, Schrader valves can experience issues, particularly leaking, which can lead to significant performance problems in the systems they serve. Understanding the anatomy of a Schrader valve is essential to diagnosing and fixing these issues.

Components of a Schrader Valve

The effectiveness of a Schrader valve relies on several key components, each playing a vital role in its operation. Recognizing these parts can aid in troubleshooting and repairs.

- Valve Body: The main structure that houses all components and connects to the valve stem, facilitating air transfer.

- Spring: This component ensures that the valve remains closed when not in use, preventing air escape.

- Pin: The pin is pressed down to open the valve and allows air to flow in or out. It is essential for the valve’s operation.

- Seal: A rubber or elastomeric seal encases the valve body to prevent leakage; wear and tear can lead to air loss.

- Threaded Stem: The outer part that screws into tires, tubes, or other components, providing a secure connection.

The integrity of the seal and proper functioning of the spring are critical for preventing leaks and ensuring reliable operation.

Common issues associated with Schrader valves include leaks due to a damaged seal or a malfunctioning spring. Regular inspection and maintenance can help identify these problems early, allowing for timely repairs and avoiding more significant issues in the future. Ensuring that the valve components are in good condition is crucial for the longevity and reliability of the applications in which they are used.

Diagnosing a Leaky Schrader Valve

Identifying a leaky Schrader valve is essential for maintaining the integrity of a tire or system. A leaky valve can lead to air loss, resulting in decreased performance and potential safety hazards. This section will Artikel the steps necessary to diagnose a leaky Schrader valve effectively.To begin the diagnosis, it is vital to conduct a thorough inspection of the valve and surrounding components.

Regular checks can help identify issues before they escalate. One of the most common methods for testing a Schrader valve for leaks involves using soapy water, which can reveal air escapes through visible bubbles. Below are the steps to diagnose a leaky Schrader valve:

Steps for Identifying a Leaky Schrader Valve

The following procedures provide a systematic approach for detecting leaks in a Schrader valve:

1. Visual Inspection

Examine the valve closely for any signs of damage, corrosion, or debris. A damaged valve may have cracks or a deteriorated rubber seal that can lead to leaks.

2. Soapy Water Test

Mix a solution of water and dish soap in a spray bottle. Spray the soapy water around the Schrader valve. If there is a leak, bubbles will form, indicating air escaping from the valve.

3. Listen for Hissing Sounds

Position your ear close to the valve after inflating the tire. A hissing sound can indicate escaping air, confirming the presence of a leak.

4. Check Tire Pressure

Regularly monitor the tire pressure using a pressure gauge. A consistent loss of pressure, even after recent inflation, may suggest a faulty Schrader valve.

5. Observe Tire Performance

Note any changes in tire performance, such as decreased responsiveness or unusual vibrations. These can be signs of air loss due to a leaky valve.Several signs can indicate that a Schrader valve may be faulty. Recognizing these signs early can help in preventing further complications and ensuring safety.

Signs of a Faulty Schrader Valve

Monitoring for specific indicators can help determine the reliability of a Schrader valve:

Frequent Tire Inflation

If the tire requires frequent inflation despite no visible punctures or damage, the Schrader valve may be leaking.

Visible Damage

Look for any visible distortions or damage to the valve core or the surrounding area. Cracked or worn-out rubber seals are immediate red flags.

Air Leakage During Checks

When performing a pressure check, if air continues to escape immediately after resealing, it indicates a potential failure of the valve.

Unusual Tire Wear

If the tire exhibits uneven wear patterns, this could also be linked to an air leak that affects the tire’s performance.By following these diagnostic steps and being vigilant about the signs of a leaky Schrader valve, one can ensure a safer and more efficient operation of tires and systems that utilize these valves. Regular maintenance and timely identification of issues can significantly enhance performance and longevity.

Tools and Materials Required for Repair

In order to effectively repair a leaky Schrader valve, having the right tools and materials is crucial. This ensures that the repair process is efficient and successful, minimizing the risk of further complications. Below is a detailed list of the essential tools and materials you will need along with necessary precautions to take during the repair.

Essential Tools for Repair

Having the appropriate tools at your disposal will streamline the repair process. Here is a list of the essential tools required to fix a leaky Schrader valve:

- Valve Core Tool: This specialized tool is designed to remove and install the valve core, allowing access to the inner components of the Schrader valve.

- Pliers: A pair of pliers may be needed to grip and manipulate components securely.

- Wrench or Socket Set: Depending on the valve fitting, a wrench or socket set may be required for loosening or tightening connections.

- Rubber Mallet: Useful for gently tapping components into place without damaging them.

- Torque Wrench: Ensures that components are tightened to the manufacturer’s specifications to avoid over-tightening.

Materials and Replacement Parts

In addition to tools, having suitable materials and replacement parts is vital for a successful repair. The following items should be gathered beforehand:

- Replacement Valve Core: It is essential to have a new valve core, as the existing one may be worn or damaged.

- O-rings or Seals: New O-rings or seals may be necessary to ensure a proper seal and prevent future leaks.

- Thread Sealant: A non-permanent thread sealant can be applied to threaded connections to enhance sealing performance.

Safety Equipment and Precautions

Ensuring safety during the repair process is of paramount importance. Here are some recommended safety equipment and precautions to consider:

- Safety Goggles: Protect your eyes from debris or pressurized air that may escape during the repair process.

- Gloves: Wear protective gloves to safeguard your hands from sharp components and chemicals.

- Ventilated Area: Ensure that you are working in a well-ventilated environment, particularly if using any sealant or adhesive that may emit fumes.

Always follow the manufacturer’s instructions and guidelines for safety and proper repair techniques to ensure the best results.

Step-by-Step Repair Procedures

Repairing a leaky Schrader valve requires precision and care to ensure effective and lasting results. This section Artikels a detailed guide for disassembling the valve for inspection, replacing the valve core, and reassembling the valve to prevent future leaks. Each step is crucial to achieving a proper seal and maintaining the functionality of the valve.

Disassembling the Schrader Valve for Inspection

Disassembling the Schrader valve is essential to identify sources of leaks and assess the condition of its components. Follow these steps for a thorough inspection:

- Begin by removing the valve from the system it is attached to, ensuring that all pressure is released.

- Use a valve core removal tool to unscrew the valve core. Turn it counterclockwise until it is completely detached.

- Inspect the valve body for any visible damage or debris. Pay close attention to the sealing surfaces.

- If necessary, clean the valve body using a soft cloth and a mild solvent to remove any residues.

- Check the valve spring for integrity; ensure it is not bent or broken.

Replacing the Valve Core

Replacing the valve core is a pivotal step when the original core is damaged or leaking. Here’s how to do it correctly:

- Select a compatible replacement valve core, as mismatch can lead to improper sealing.

- Using the valve core removal tool, gently insert the new core into the valve body.

- Screw the new core into place by turning it clockwise until it is snug but do not overtighten, as this can damage the core or valve body.

- Ensure that the core is seated properly by pressing it down slightly; you should feel resistance from the spring.

Reassembling the Valve and Ensuring a Proper Seal

Once the valve core is replaced, reassembling the valve is the final step, critical for preventing future leaks. Use the following methods to ensure a reliable seal:

- Before reassembly, inspect the O-ring or sealing washer for wear. Replace it if it appears cracked or flattened.

- Apply a small amount of thread sealant or plumber’s tape to the threads of the valve body before reattaching it to the system.

- Tighten the valve body securely but avoid using excessive force which may damage the threads.

- After reassembly, inflate the system and check for leaks by applying a soapy water solution to the valve; bubbles indicate leaks that need addressing.

“Maintaining a proper seal is crucial in preventing future leaks and ensuring optimal performance of the Schrader valve.”

Maintenance Tips for Schrader Valves

Schrader valves are integral components in various applications, from automotive tires to bicycle tubes. To ensure their longevity and efficiency, regular maintenance is essential. Proper care can prevent leaks and other issues that may arise from wear and tear. Implementing preventive maintenance techniques can minimize the risk of malfunction and extend the lifespan of your Schrader valves.

A proactive approach to maintaining Schrader valves involves routine inspections and the use of compatible materials during repairs. This ensures the integrity of the valves and optimizes their performance. Below are key maintenance tips and practices to keep your Schrader valves in excellent condition.

Preventive Maintenance Techniques

Regular maintenance helps detect potential issues before they escalate into significant problems. Here are some recommended practices:

- Regular Cleaning: Periodically clean the valve exterior with a damp cloth to remove dirt and debris that may compromise the seal.

- Lubrication: Apply a small amount of lubricant around the valve threads to ensure smooth operation and prevent corrosion.

- Visual Inspection: Frequently check the valve for signs of wear, such as cracks or deformities, which can result in leaks.

- Pressure Checks: Regularly monitor the pressure in tires or systems utilizing Schrader valves to detect any gradual loss of air, indicating a potential leak.

- Environmental Protection: Store equipment with Schrader valves in a climate-controlled environment to avoid exposure to extreme temperatures and humidity.

Routine Inspection Checklist

To ensure the ongoing integrity of Schrader valves, here is a checklist for routine inspections that can be performed easily:

- Check for Air Leaks: Use soapy water around the valve to identify any bubbling, which indicates a leak.

- Examine Valve Stem: Ensure the valve stem is straight and undamaged, as any bending can affect performance.

- Tightness of the Valve Core: Confirm the valve core is secure to prevent air loss.

- Inspect Sealing Gasket: Review the condition of the sealing gasket for wear or degradation, as this is crucial for maintaining air pressure.

- Evaluate Compatibility of Components: Verify that any replacement components are compatible with the existing valve system to avoid further complications.

Importance of Using Compatible Materials

Using compatible materials when replacing valve components is paramount for maintaining optimal function. Incompatible materials can lead to premature failure or leaks, which necessitates frequent repairs. Some critical points to consider include:

- Material Compatibility: Ensure that replacement valve cores and seals match the specifications of the original components.

- Quality of Components: Opt for high-quality materials that meet industry standards to enhance durability.

- Manufacturer Recommendations: Always refer to the manufacturer’s guidelines regarding materials and replacement parts to ensure safety and reliability.

“Investing time in regular maintenance and using compatible materials significantly reduces the likelihood of valve failures, ensuring a safer and more efficient operation.”

Troubleshooting Common Issues After Repair

Even after a successful repair, persistent leaks can be frustrating and may indicate underlying issues that need to be addressed. Understanding the troubleshooting process is crucial for ensuring the longevity of your Schrader valve and maintaining optimal performance. This section Artikels essential steps to follow if leaks continue after repair, assesses potential damages to the valve seat, and discusses alternative solutions for ongoing issues.

Steps to Diagnose Persistent Leaks

If you find that the valve still leaks after attempting repairs, follow these systematic steps to identify the source of the problem:

1. Reinspect the O-ring

The O-ring should be checked for any signs of wear, misalignment, or damage. A compromised seal can lead to air leakage.

2. Check Tightness

Ensure that the valve core is tightly secured. Sometimes, the core may appear tight but could be slightly loose, allowing air to escape.

3. Examine the Valve Body

Inspect the valve body for any visible cracks or damages that may have been missed during the initial repair.

4. Test with Soapy Water

Apply a mixture of soap and water to the valve and observe for bubbles. Bubbles will indicate the precise location of any air leaks.

5. Assess External Factors

Environmental conditions or improper inflation techniques might also contribute to perceived leaks. Ensure the valve is not exposed to extreme temperatures or physical stress.

Assessment of Valve Seat Condition

The valve seat plays a critical role in maintaining a proper seal within the Schrader valve. An assessment of its condition is essential for effective troubleshooting.

Visual Inspection

Look for any visible signs of damage or deformation on the valve seat. A damaged seat may compromise the valve’s ability to seal effectively.

Check for Debris

Ensure that the valve seat is free of dirt or debris. Contaminants can prevent the O-ring from forming a proper seal, leading to leaks.The implications of a damaged valve seat can be significant, as it may require complete replacement of the valve to restore functionality. If the seat is found to be damaged, it is essential to stop using the valve until repairs are made to prevent further air loss.

Alternative Solutions for Ongoing Leaks

When all standard repair efforts have been exhausted and leaks persist, consider the following alternative solutions:

Replace the Valve Core

If the core has sustained damage beyond repair, replacing it can often restore functionality without the need for a complete valve replacement.

Install a New Schrader Valve

When leaks are still present after multiple repairs, replacing the entire valve may be the most effective solution. Ensure that the new valve is compatible with the application and properly installed.

Professional Assessment

In some cases, it may be necessary to consult with a professional. Experts can provide insight into potential issues that an untrained eye might overlook.By following these troubleshooting steps, assessing the valve seat, and exploring alternative solutions, you can effectively address persistent leaks in your Schrader valve and maintain optimal performance in your equipment.

When to Seek Professional Help

Recognizing the right moment to consult a professional technician for repairs can be crucial in ensuring the longevity and proper functioning of your Schrader valve. While many minor issues can be managed through DIY methods, certain scenarios necessitate expert intervention for optimal results and safety.

Professional help is advised in various situations, particularly when the problem exceeds basic repairs or involves complex issues that require specialized knowledge and tools. For instance, if the Schrader valve is severely damaged, or if the leak persists despite your best repair efforts, engaging a technician is essential. Experts have the experience to handle complications that may not be immediately apparent to the average DIY enthusiast.

Benefits of Consulting a Technician

Consulting a qualified technician can provide several advantages that enhance the repair process and outcomes. Understanding these benefits can guide your decision-making when faced with complicated repairs:

- Expertise: Technicians possess specialized training and knowledge, allowing them to diagnose and resolve issues more efficiently than most DIY methods.

- Advanced Tools: Professionals have access to specific tools and equipment designed for precise valve repairs, ensuring better outcomes.

- Warranty and Safety: Many technicians offer warranties on their work, providing peace of mind that issues will be addressed if they recur. This reduces the risk of further complications that could arise from improper repairs.

- Time Efficiency: Hiring a professional can save time; their experience allows them to perform repairs quickly and effectively.

Tips for Selecting a Qualified Professional

Choosing the right technician for your Schrader valve repairs is vital for achieving satisfactory results. Consider the following guidelines to ensure you select a qualified professional:

- Check Credentials: Look for certifications or licenses that indicate the technician’s qualifications and knowledge in valve repairs.

- Read Reviews: Research online reviews and testimonials from previous customers to gauge the technician’s reliability and quality of work.

- Request Quotes: Obtain estimates from multiple professionals to compare prices and services, ensuring you receive fair value.

- Inquire About Experience: Ask how long the technician has been in business and whether they have specific experience with Schrader valves.

- Confirm Warranty Policies: Discuss warranties on parts and labor to ensure your investment is protected.

Concluding Remarks

In conclusion, addressing a leaky Schrader valve promptly can save you time and resources while ensuring optimal performance in your system. By understanding the components, following the correct repair procedures, and implementing regular maintenance, you can prevent future leaks and extend the life of your valves. Should you encounter persistent issues, remember that seeking professional assistance is always a wise choice to ensure safety and effectiveness.