How to Replace a Frayed Shifter Cable is an essential guide for ensuring your vehicle operates smoothly, as shifter cables play a crucial role in the overall performance of your car. A frayed shifter cable can significantly hinder your ability to change gears, leading to potential safety hazards and costly repairs if left unaddressed.

In this article, we will explore the various aspects of shifter cables, from understanding their function and identifying signs of wear to the tools needed for replacement and the steps involved in performing the task successfully. Whether you are a seasoned DIY enthusiast or a novice, this guide will equip you with the knowledge necessary for a successful cable replacement.

Understanding Shifter Cables

Shifter cables play a crucial role in the operation of a vehicle’s transmission system. They serve as the link between the shifter lever inside the vehicle and the transmission itself, facilitating the communication necessary for changing gears. Understanding how these cables function and recognizing their condition is vital for maintaining optimal vehicle performance.The primary function of shifter cables is to transmit the driver’s input from the gear shift to the transmission, allowing for smooth transitions between different gears.

These cables are designed to withstand tension and movement as the driver operates the shifter, and they typically consist of durable materials to endure wear and tear over time.

Signs of a Frayed Shifter Cable

It is essential to recognize the signs of a frayed shifter cable promptly to prevent further damage to the vehicle. A frayed cable can lead to difficulties in shifting gears and may compromise vehicle safety. Common indicators of a frayed shifter cable include:

- Difficulty in shifting gears, which may manifest as a sticky or unresponsive shifter.

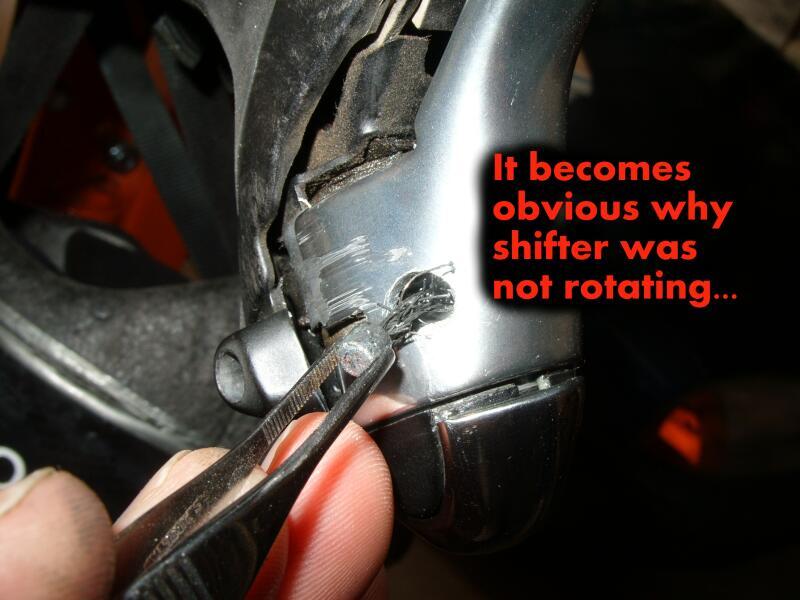

- Visible wear or fraying on the cable itself, which can often be identified by inspecting the cable housing.

- Unusual noises, such as grinding or popping sounds, when attempting to change gears, often indicating internal issues.

- Unexpected gear changes, where the vehicle may shift gears on its own, pointing to a malfunction in the cable connection.

Impact of a Frayed Shifter Cable on Vehicle Performance

A frayed shifter cable can significantly affect the overall performance of a vehicle. When the cable is compromised, it can lead to a litany of issues that not only hinder the driving experience but also pose risks to safety. The following points highlight the potential impacts on vehicle performance:

- Increased difficulty in gear engagement can lead to a delayed or harsh shifting experience, making it challenging to control the vehicle effectively.

- Potential for transmission damage, as improper shifting can place undue stress on the transmission components, resulting in costly repairs.

- Loss of acceleration or power, as a malfunctioning cable may prevent the vehicle from shifting into higher gears, thus limiting speed and performance.

- Risk of complete failure to shift, which can immobilize the vehicle and pose a danger while driving.

Early detection and replacement of frayed shifter cables can prevent severe mechanical failures and ensure a safer, more reliable driving experience.

Tools Required for Replacement

To successfully replace a frayed shifter cable, having the right tools is essential. The correct tools not only streamline the process but also ensure a safe and effective repair. Below is a detailed list of tools categorized into hand tools, specialty tools, and safety equipment, each accompanied by a brief explanation of its function.

Hand Tools

Hand tools are fundamental for various tasks involved in the shifter cable replacement. These tools allow for manual intervention and adjustments easily.

- Screwdriver Set: A set of screwdrivers, including both flathead and Phillips, is needed to remove screws securing the shifter assembly and other components.

- Wrenches: A combination of adjustable and fixed wrenches is necessary for loosening and tightening nuts that hold the cable in place.

- Side Cutters: These pliers are useful for cutting the frayed cable and trimming any excess material during installation.

- Torque Wrench: This tool is essential for ensuring that bolts are tightened to the manufacturer’s specifications, preventing damage and ensuring safety.

Specialty Tools

Specialty tools are designed specifically for tasks related to shifter cables, ensuring a more efficient replacement process.

- Cable Crimping Tool: This tool is used to securely attach cable ends to the new shifter cable, providing a strong and reliable connection.

- Cable Housing Cutter: A specialized cutter that allows for clean and precise cuts on the cable housing, ensuring a proper fit and function.

- Housing Ferrule Crimp Tool: This tool is used for crimping the ferrules onto the cable housing, which helps in securing the cable during operation.

Safety Equipment

Safety equipment is crucial to protect yourself while working on vehicle components. Proper safety gear minimizes the risk of injury during the repair process.

- Safety Glasses: Protect your eyes from debris and potential hazards when working with tools or while cutting cables.

- Gloves: Wearing gloves helps to protect your hands from sharp edges and provides a better grip on tools.

- Ear Protection: If using power tools, ear protection is recommended to prevent hearing loss from prolonged exposure to high noise levels.

Preparing for the Replacement

Before initiating the process of replacing a frayed shifter cable, it is essential to adequately prepare both the vehicle and the workspace. This preparation will ensure not only a smoother replacement process but also enhance safety for the individual carrying out the task. Taking the necessary precautions and gathering the right tools beforehand minimizes the risk of errors and accidents.To start, ensuring safety is paramount.

Engaging in vehicle maintenance requires attention to detail, especially when dealing with components that directly affect the operation of the vehicle. The following safety precautions should be adhered to before beginning the replacement process:

Safety Precautions

Prioritizing safety can prevent accidents and injuries during the replacement process. It is important to consider the following precautions:

- Ensure the vehicle is parked on a flat, stable surface to prevent rolling.

- Engage the parking brake firmly to secure the vehicle in place.

- Disconnect the negative terminal of the battery to prevent electrical shorts or accidental shifts.

- Utilize safety glasses and gloves to protect yourself from debris and sharp edges.

- Ensure proper ventilation in the workspace, especially if working in a closed area.

In addition to safety measures, assessing readiness for the replacement process involves checking off essential tools and materials. The following checklist can serve as a guide to ensure nothing is overlooked:

Preparation Checklist

Having all necessary tools and materials on hand will streamline the replacement process. The following checklist provides an overview of items required:

- Replacement shifter cable specific to your vehicle’s make and model.

- Wrenches and sockets for cable removal and installation.

- Cutting tool for removing the old frayed cable, if necessary.

- Screwdrivers (both flat-head and Phillips) for various fasteners.

- Zip ties or clamps to secure the new cable in place.

- Lubricant for smooth cable operation post-installation.

Taking the time to prepare adequately ensures that the replacement of the shifter cable is not only effective but also safe. This thoughtful approach can significantly reduce the likelihood of complications arising during the process, leading to a more successful outcome.

Step-by-Step Replacement Procedure

Replacing a frayed shifter cable is an essential maintenance task that ensures smooth gear shifting and enhances driving safety. The following sections will guide you through the detailed procedures of removing the old shifter cable and installing the new one, along with crucial adjustments and routing considerations.

Removing the Old Shifter Cable

Before beginning the removal process, it’s important to understand the attachment points of the shifter cable to ensure a smooth disconnection. Start by locating the shifter assembly and the point where the cable connects to the transmission.

1. Disconnect the Battery

Begin by disconnecting the negative terminal of the battery to prevent any electrical short-circuiting during the procedure.

2. Access the Shifter Assembly

Remove any trim pieces or covers around the shifter, using appropriate tools to avoid damage.

3. Unhook the Cable

Locate the cable connection at the shifter. This usually involves releasing a clip or tab to detach the shifter cable from the shifter assembly.

4. Remove Cable from Transmission

Next, trace the cable to the transmission. There will typically be a retaining clip securing the cable to the transmission linkage. Carefully remove this clip and gently pull the cable out of its housing.

5. Inspect the Old Cable

Take a moment to inspect the old cable for wear and any additional damage that may have contributed to its fraying.

Installing the New Shifter Cable

Once the old cable is removed, installation of the new shifter cable should be done with care to ensure proper functionality. Follow these steps:

1. Prepare the New Cable

Before installation, ensure that the new cable is the correct length and type for your vehicle model.

2. Route the New Cable

Begin routing the new cable through the same path as the old one. It is crucial for the cable to be free of any obstructions and to avoid contact with sharp edges or hot surfaces.

3. Connect to the Transmission

Insert the new cable into the transmission linkage. Ensure that it is seated correctly and secure it with the retaining clip.

4. Attach to the Shifter Assembly

Carefully insert the cable into the shifter assembly and secure it by locking in the clip or tab, ensuring a snug fit.

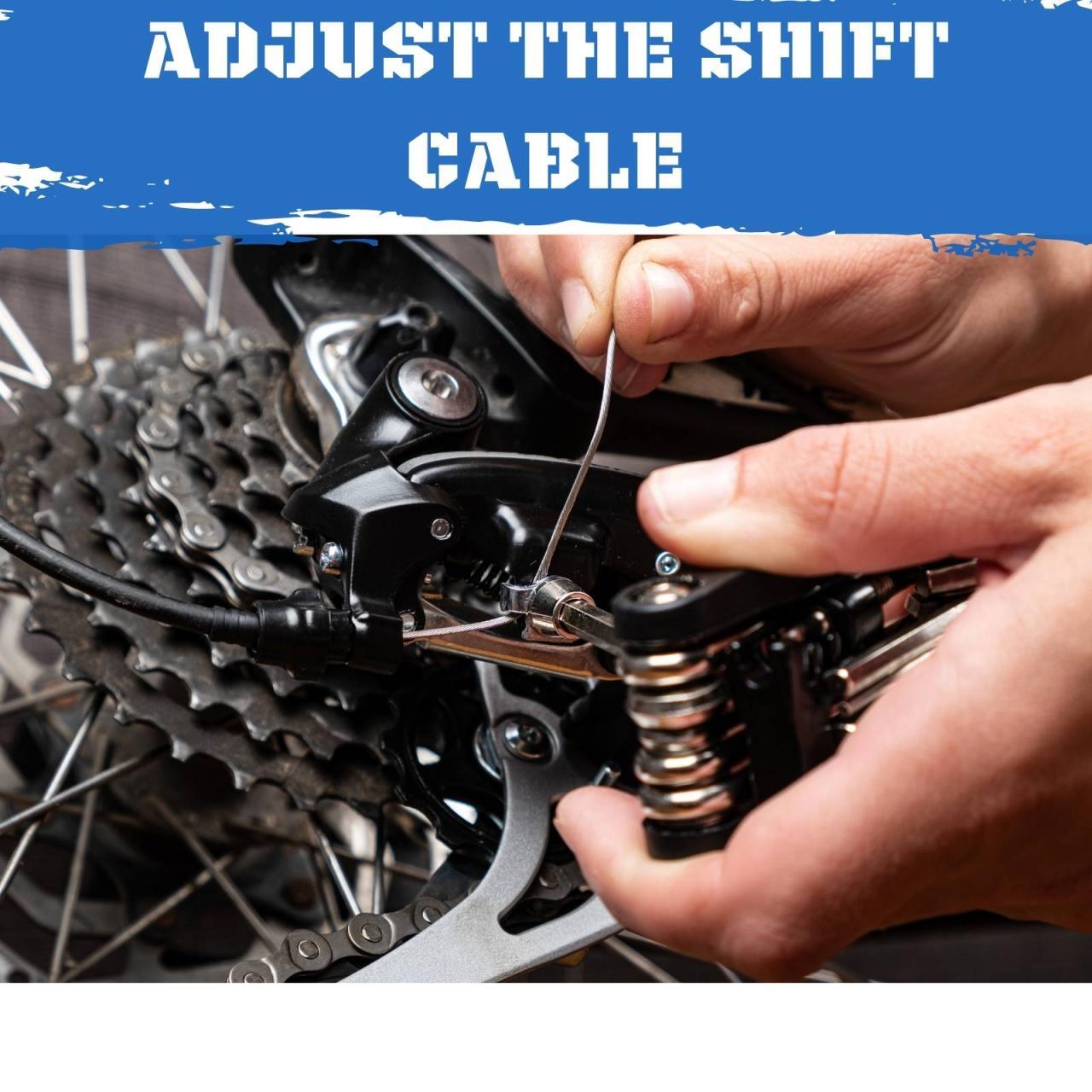

5. Adjust Cable Tension

Most shifter cables will require some degree of tension adjustment. Refer to your vehicle’s service manual for the specific tension specification and adjust accordingly. This can usually be done by turning an adjustment nut located along the cable.

Proper Routing of the New Cable

Proper routing of the shifter cable is vital for optimal performance. This step can affect the ease of gear shifting and longevity of the cable.

Follow Original Routing

Always follow the original routing of the old cable as a reference. Ensure the new cable has the same bends and curves to prevent kinks.

Use Cable Guides

If your vehicle has pre-installed cable guides or clips, ensure that the new cable is secured within these guides to minimize movement and wear.

Check for Interference

After routing, inspect to confirm that the cable is not in contact with any moving parts, exhaust components, or areas susceptible to high heat.

Test Movement

With the cable fully installed and routed, manually test the shifter movement without starting the vehicle. This will help ensure that no binding occurs.Following these steps diligently will help you successfully replace the shifter cable, ultimately contributing to a safer and more reliable driving experience.

Common Mistakes to Avoid

Replacing a frayed shifter cable can significantly enhance the performance of your bicycle, yet there are common pitfalls that can lead to suboptimal results. It is essential to be aware of these mistakes and adopt strategies to avoid them, ensuring a smooth and effective replacement process. This section Artikels frequent errors, the ramifications of improper installation, and troubleshooting tips for issues that may arise post-replacement.

Frequent Errors During Replacement

Certain mistakes often occur during the shifter cable replacement process that can lead to improper functionality. Awareness of these errors can assist in achieving a successful installation.

- Incorrect Cable Routing: Failing to route the cable properly may result in shifting issues. Ensure the cable follows the manufacturer’s specified path, avoiding sharp bends or twists.

- Inadequate Tension Adjustment: Not adjusting the cable tension correctly can affect shifting responsiveness. Always ensure the cable is taut but not overly tight during installation.

- Failure to Lubricate: Neglecting to lubricate the cable and housing can lead to friction, resulting in poor shifting performance. Use appropriate lubricants, following the manufacturer’s recommendations.

- Improper Tool Usage: Using the wrong tools for cutting or crimping can damage the cable ends. Utilizing the correct tools ensures a clean cut and secure fittings.

- Neglecting to Test: Skipping the testing phase after installation can lead to missed issues. Always conduct a thorough check of shifting before concluding the replacement.

Consequences of Improper Installation

Improper installation of a shifter cable could lead to several adverse outcomes that can affect the overall cycling experience.

“An improperly installed shifter cable can lead to frustrating missed shifts and increased wear on components.”

Issues arising from incorrect installation include:

- Continuous skipping of gears, which can compromise safety and ride quality.

- Increased wear on the derailleur and cassette, resulting in more frequent maintenance or replacements.

- Risk of the cable snapping during use, leading to potential accidents or falls.

Troubleshooting Post-Replacement Issues

After replacing a shifter cable, it’s important to monitor for any issues that may arise. Implementing troubleshooting steps can help to quickly identify and resolve problems, restoring optimal bike functionality.When facing difficulties with shifting after replacement, consider the following tips:

Recheck Cable Tension

If shifts feel unresponsive or clunky, re-evaluate the cable tension to ensure it is neither too loose nor too tight.

Inspect for Cable Friction

Examine the cable housing for any obstructions or kinks that may be causing friction. Cleaning or re-routing may be necessary.

Validate Derailleur Alignment

Ensure that the derailleur is properly aligned. Misalignment can result in poor shifting performance and may require adjustment.

Test Shifting Under Load

Perform a test shift while riding if possible, as this can reveal issues that may not occur when the bike is stationary.By carefully avoiding these common mistakes and being proactive in troubleshooting, one can ensure a successful and effective replacement of the shifter cable, contributing to a smoother cycling experience.

Maintaining Shifter Cables

Proper maintenance of shifter cables is essential for ensuring the longevity and performance of your bicycle’s shifting system. Regular checks and maintenance can help identify issues before they escalate, preventing costly repairs and ensuring a smooth ride. By following a consistent maintenance schedule and adopting effective care practices, cyclists can extend the lifespan of their shifter cables significantly.Periodic checks of shifter cables can help identify wear or damage early.

It is advisable to develop a maintenance schedule that aligns with your riding frequency and conditions. Here is a suggested schedule:

Maintenance Schedule for Shifter Cables

Establishing a routine for inspecting and maintaining shifter cables is crucial. This schedule can vary based on usage and environmental factors. Below is a recommended maintenance timeline:

- Every Ride: Inspect shifter cables for visible wear, fraying, or kinks. Ensure that the cable housing is intact and free of dirt.

- Weekly: Clean the cables and housing with a damp cloth to remove grime and dirt buildup that may affect performance.

- Monthly: Apply a light lubricant to the cable to reduce friction and prevent corrosion.

- Seasonally: Conduct a thorough inspection of the entire shifter system, including the shifters, cables, and derailleur alignment. Replace cables that show signs of wear.

Practices to Extend the Lifespan of Shifter Cables

Implementing specific practices can significantly enhance the durability of shifter cables. Focusing on the following methods will ensure that your cables remain in optimal condition for an extended period.

- Keep cables clean and free of contaminants by regularly wiping them down and ensuring the housing is clear of obstructions.

- Store the bicycle indoors or in a sheltered environment to protect cables from harsh weather conditions, which can lead to rust and deterioration.

- Avoid exposing shifter cables to extreme temperatures, as this can weaken the cable materials over time.

- Ensure proper cable tension is maintained; too much tension can cause undue stress, while too little can lead to ineffective shifting.

Environmental Factors Affecting Shifter Cable Longevity

Environmental conditions play a significant role in the longevity of shifter cables. Recognizing how these factors impact cable performance can help cyclists make informed decisions for maintenance and care.

- Humidity: High humidity levels can lead to corrosion, especially if cables are exposed to moisture without proper protection.

- Temperature Variability: Extreme cold can cause materials to become brittle, while intense heat may lead to expansion and potential cable damage.

- Exposure to Elements: Riding in wet, muddy, or sandy conditions can wear down cables more quickly. Cleaning the bike after exposure to these elements is crucial.

- UV Radiation: Prolonged exposure to sunlight can degrade plastic coatings on cables, making them more susceptible to fraying.

When to Seek Professional Help

In certain situations, attempting a do-it-yourself (DIY) approach to replace a frayed shifter cable may not be the best course of action. Recognizing when to seek professional help can save time, prevent further damage, and ensure the job is done correctly. Various circumstances indicate that enlisting the expertise of a qualified mechanic is advisable.Complexity of the IssueSome issues related to shifter cables may stem from underlying problems that are not immediately evident.

These could include a malfunctioning transmission, misalignment of components, or electrical issues in automated shifters. If the symptoms extend beyond a frayed cable—such as erratic shifting, slippage, or unusual noises—it is prudent to consult a professional. Mechanics have the experience and diagnostic tools to identify and resolve these complex problems.

Potential Risks of DIY Replacement

Engaging in DIY repairs carries inherent risks, particularly for those without extensive experience. While replacing a frayed shifter cable might seem straightforward, the following points illustrate potential pitfalls:

- Inaccurate Installation: Improperly installed cables can lead to shifting issues, potentially damaging the transmission over time.

- Increased Repair Costs: Mistakes made during a DIY attempt can result in higher repair costs if the vehicle requires additional work as a result.

- Safety Concerns: Inadequate repairs might lead to safety hazards while driving, such as sudden loss of gear engagement.

These risks highlight the importance of evaluating one’s own skills and knowledge before deciding on a DIY approach.

Selecting a Qualified Mechanic for Shifter Cable Issues

When professional assistance is deemed necessary, selecting a qualified mechanic is crucial. The following considerations can help ensure that you choose the right professional for the job:

- Experience and Specialization: Look for mechanics who specialize in transmission work and have substantial experience with your vehicle make and model.

- Certifications: Verify that the mechanic possesses relevant certifications, such as those from the National Institute for Automotive Service Excellence (ASE).

- Customer Reviews: Research customer reviews and testimonials to gauge the mechanic’s reputation and reliability.

- Warranty and Guarantees: Inquire about warranties on labor and parts, which can provide peace of mind regarding the quality of the work performed.

By carefully selecting a qualified mechanic, vehicle owners can ensure that their shifter cable and related issues are handled effectively and safely.

Epilogue

In conclusion, knowing how to replace a frayed shifter cable not only enhances your vehicle’s performance but also ensures your safety on the road. By following the Artikeld procedures, avoiding common mistakes, and adhering to a maintenance schedule, you can prolong the lifespan of your shifter cables and improve your driving experience. Should you encounter challenges, remember that seeking professional help is always a viable option to secure the best results.